Snack packaging machines have changed how snack foods are processed, preserved, and presented to consumers. With increasing consumer demand for convenience, freshness, and portability, the type of packaging plays a critical role in branding and market success. One of the most important questions for manufacturers and businesses entering this space is: What types of bags can snack packaging machines pack?

In this comprehensive guide, we’ll explore the various bag types compatible with snack packaging machines, their applications, advantages, and considerations. Along the way, we will also highlight insights on choosing the best snack packaging machine, features offered by top snack packaging machine manufacturers, particularly in regions such as China, known for its low-cost snack packaging machine production and granule packaging machine factories.

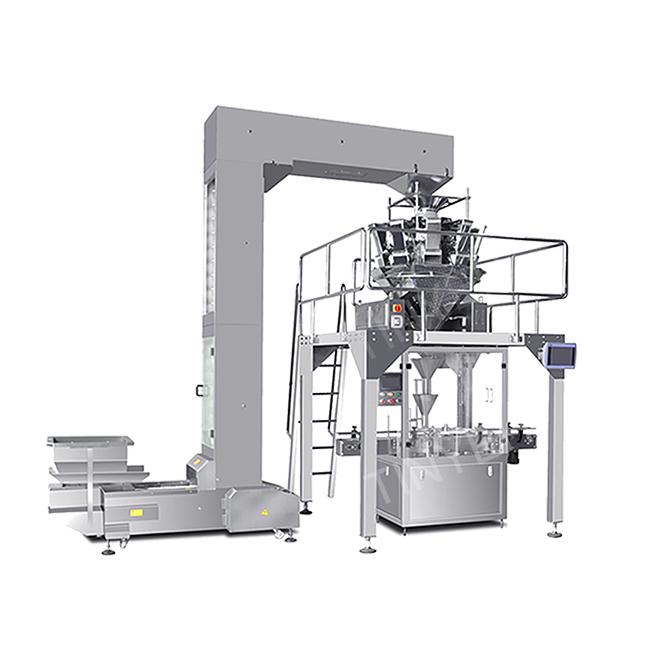

Low-Cost Snack Packaging Machine

1. Pillow Bags: The Most Common Snack Packaging Option

Pillow bags are arguably the most widely used packaging style in the snack industry. Their simple, rectangular shape, ease of production, and high-speed packaging compatibility make them ideal for a wide variety of snacks.

Commonly Packed Snacks:

● Potato chips

● Pretzels

● Nuts

● Candies

● Popcorn

Advantages:

● Compatible with high-speed snack packaging machines

● Cost-effective material usage

● Minimal sealing surface for air-tight sealing

● Works with vertical form fill seal (VFFS) machines

Snack packaging machines equipped with multi-head weighers can precisely fill pillow bags with granular or lightweight products. These machines are common in any granule packaging machine factory producing consumer-ready snack pouches.

2. Gusseted Bags: Enhanced Stability and Shelf Presence

Gusseted bags have side folds that expand when the bag is filled. This structure offers greater volume and better shelf presentation.

Commonly Packed Snacks:

● Granola

● Trail mix

● Bulk nuts or dried fruits

Advantages:

● Increased internal volume

● Excellent for stacking and display

● Can be used with snack packaging machines in China, offering adjustable sealing jaws

Machines capable of packaging gusseted bags tend to be slightly more advanced, but many hot-selling snack packaging machines offer this functionality out of the box. Businesses looking to scale up can find such models listed among snack packaging machines for sale online or directly from international snack packaging machine manufacturers.

3. Stand-Up Pouches (Doypacks): The Premium Retail Choice

Stand-up pouches, often referred to as Doypacks, have become increasingly popular for premium snack products. These bags have a flat base that allows them to stand upright, making them ideal for retail display.

Commonly Packed Snacks:

● Organic chips

● Gourmet popcorn

● Freeze-dried fruits

● Protein bars or bites

Advantages:

● Strong brand visibility on shelves

● Reclosable features (zip locks, spouts)

● Suitable for both dry and semi-moist snacks

Stand-up pouch packaging typically requires a horizontal snack packaging machine or a rotary pouch packaging machine. Although these may have a higher snack packaging machine price, their impact on branding and user experience often justifies the investment.

4. Quad-Seal Bags: For Heavier or High-Volume Snacks

Quad-seal bags have seals on four corners, providing extra stability and strength. They're common in snacks sold in large quantities or premium formats.

Commonly Packed Snacks:

● Bulk granola or cereals

● Family-sized chips or crackers

● Pet snacks and food

Advantages:

● Great shape retention

● Supports heavier fill weights

● Professional appearance

Quad-seal bags require robust and often high-speed snack packaging machines capable of handling complex sealing and filling mechanisms. Brands targeting wholesale markets or large-scale retail distribution often prefer this format.

5. Sachets and Stick Packs: Single-Serve Convenience

For portion-controlled snacks or seasoning packets included in snack combo packs, sachets and stick packs are ideal.

Commonly Packed Snacks:

● Trail mix seasoning

● Dried fruits

● Protein powder portions

● Nut butter servings

Advantages:

● Ideal for on-the-go consumption

● Minimal packaging waste

● Low packaging cost

These formats are handled by multi-lane snack packaging machines, often customized at a snack packaging machine manufacturer's facility to meet specific product needs. They're commonly used by health food companies, gym-focused brands, and convenience snack producers.

6. Flat Bottom Bags: A Fusion of Form and Function

Flat bottom bags combine the best aspects of gusseted and stand-up pouches. They have a reinforced bottom, vertical sides, and strong shelf presence.

Commonly Packed Snacks:

● Baked snacks

● Trail mix

● Mixed dried fruits

● Premium biscuits

Advantages:

● Multiple printing surfaces for branding

● Excellent stability

● Modern, appealing look

Though typically more expensive, many best snack packaging machines offer flat-bottom bag compatibility, often found in automatic rotary packing machines. Businesses seeking premium appeal should consider these bags as part of their packaging strategy.

7. Custom Shaped Bags: Unique Branding Opportunities

To stand out in a crowded snack aisle, some brands use custom die-cut bags. These may be shaped like stars, characters, or thematic icons.

Commonly Packed Snacks:

● Children's snacks

● Holiday-themed treats

● Co-branded or limited-edition products

Advantages:

● Maximum shelf impact

● Ideal for promotional campaigns

● Increases brand memorability

These require specialized snack packaging machines and often necessitate direct collaboration with a snack packaging machine manufacturer for custom mold development. This adds to the snack packaging machine price, but the marketing payoff can be substantial.

Choosing the Right Snack Packaging Machine for Your Bag Type

When selecting a snack packaging machine, businesses must consider:

● Bag compatibility: Can the machine handle different bag formats?

● Speed: Does it meet your production volume needs?

● Automation: Is it semi-automatic or fully automatic?

● Cost: What’s your budget vs. the snack packaging machine price?

Additionally, whether you’re sourcing a low-cost snack packaging machine or a high-speed snack packaging machine, working with a reputable snack packaging machine manufacturer is critical. Many international buyers prefer purchasing from a snack packaging machine in China due to cost-effectiveness and wide equipment options.

Application Scenarios Across the Snack Industry

Snack packaging machines are used in a wide variety of scenarios, including:

● Snack food production lines

● Pet food manufacturers

● Cereal and breakfast food companies

● Gourmet food businesses

● Granule packaging machine factory setups

High-Speed Snack Packaging Machine in China

Conclusion

Snack packaging machines are versatile and capable of handling a wide array of bag types—from pillow bags and stand-up pouches to custom die-cut shapes. The bag style you choose impacts everything from brand perception to shelf stability and cost-efficiency.

To meet diverse packaging needs, you must evaluate their product type, volume, and market positioning. Whether you need a hot sale snack packaging machine for a new product launch or the best snack packaging machine for established production, understanding the bag options is the first step to effective packaging success.

Looking for the best snacks packing machine price? Tinyeh offers competitive pricing without compromising quality or functionality. Each machine is engineered for durability, ease of use, and optimal performance, making us a trusted snacks packing machine manufacturer worldwide. Choose Tinyeh for reliable snack packaging solutions that maximize productivity and ensure the freshness of your products.