In modern packaging lines where speed, precision, and efficiency are paramount, multihead weigher packing machines have become indispensable. These machines now represent cutting-edge technology in the automated packaging machinery landscape.

What Is a Multihead Weigher Packing Machine?

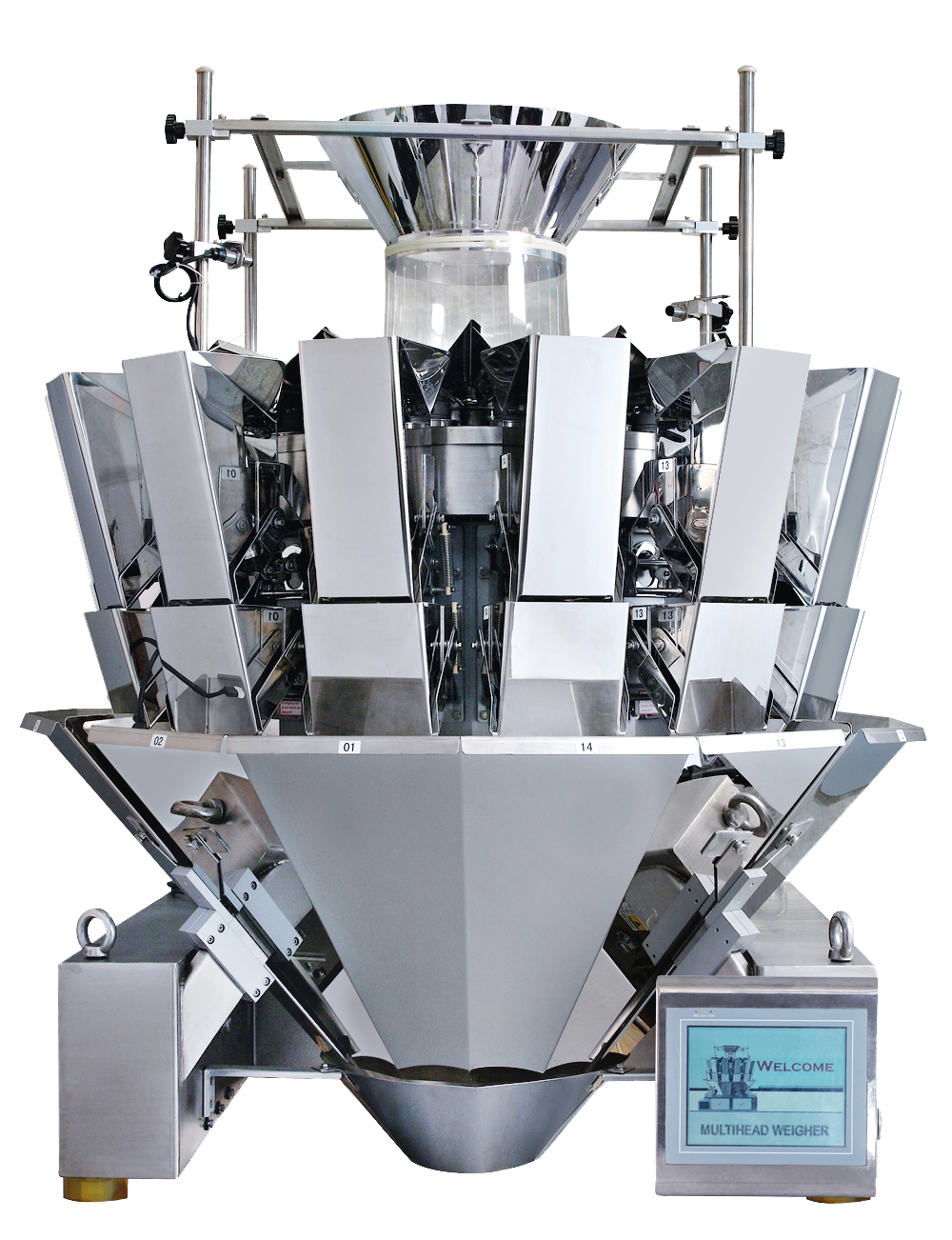

A multihead weigher packing machine, also known as a combination weigher, is an automated system used primarily for weighing and packaging granular or irregular-shaped products with high speed and precision. It comprises multiple heads (typically 10 to 32) arranged in a circular formation around a central dispersion system. Each head contains a load cell that weighs a small portion of the product.

The machine calculates the optimal combination of weights from different heads that add up to the target weight with the smallest possible margin of error. Once the ideal combination is determined, the product is discharged into packaging — whether it's a bag, tray, container, or pouch.

Tinyeh Multihead Weigher Packing Machine

How Does a Multihead Weigher Packing Machine Work?

Here's a breakdown of its operational process:

Product Feeding: Product is fed into a top cone feeder that evenly distributes it to individual linear feeders.

Weighing: The product passes into weigh hoppers, each equipped with a load cell to measure the content's weight.

Combination Algorithm: An onboard microprocessor uses advanced algorithms to calculate the best weight combination from available hoppers to reach the closest match to the target weight.

Discharge: The system discharges selected hoppers into the packaging system, typically a vertical form fill seal (VFFS) machine, or other types of automatic pouch packing machines.

Key Benefits of Multihead Weigher Packing Machines

Exceptional Accuracy: Multihead weighers offer unparalleled precision, typically achieving an accuracy of ±0.5g depending on the product. This results in minimal product giveaway, which is crucial for reducing costs, especially in high-volume packaging.

High-Speed Operation: With the ability to weigh and discharge up to 120 weighments per minute, these machines dramatically improve productivity compared to manual or single-head systems.

Versatility in Product Handling: From sticky, fragile, and dry products to frozen items, multihead weighers can handle a broad range of product types. For example:

● Snacks and confectionery: Potato chips, gummies, candies

● Frozen food: Frozen vegetables, dumplings

● Granular products: Rice, sugar, beans

● Hardware and non-food items: Bolts, screws, plastic components

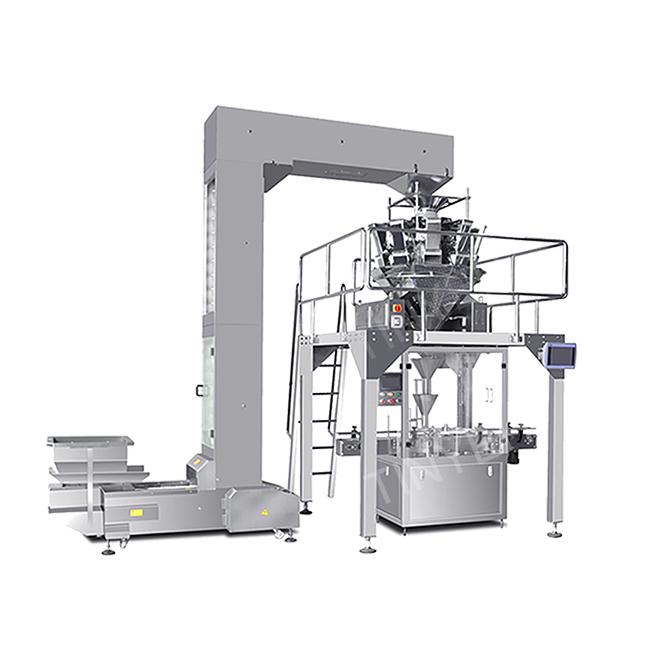

Automation and Labor Cost Reduction: These systems are often part of a fully automated packing line, integrating seamlessly with other components such as conveyors, checkweighers, metal detectors, and carton sealing machines, reducing the reliance on manual labor and improving packaging consistency.

Hygienic and Food-Safe Design: Most food-grade models feature stainless steel construction, smooth surfaces, and tool-free dismantling for easy cleaning, aligning with HACCP and FDA standards.

Applications Across Industries

Multihead weighers are now found across diverse sectors:

Food Industry: For packing granular, irregular, or fragile products like dried fruits, meatballs, salad leaves, cereals, and nuts.

Pharmaceutical Packaging: For precisely dosing capsules, tablets, and small medicinal items.

Chemical Industry: Granular detergents, fertilizer beads, or chemical pellets.

Hardware Packaging: For high-volume packing of bolts, nuts, screws, and small components.

Their integration into vertical packaging machines, rotary premade pouch packing machines, or tray sealers makes them an ideal fit for almost any packaging format.

Key Design Trends and Innovations

Modular Construction: Many manufacturers now offer modular weigher designs, allowing easy maintenance and replacement of individual weighers without affecting the whole system.

AI and Smart Weighing Algorithms: Some advanced systems now use AI-powered control software to dynamically adjust combination algorithms based on product behavior, temperature, and feeding consistency, improving throughput and reducing human intervention.

Integration with Industry 4.0 Systems: IoT-enabled multihead weighers allow remote monitoring, predictive maintenance, and real-time data logging — ideal for manufacturers moving toward smart factory solutions.

Compact Footprints for Space Optimization: As floor space becomes more valuable, there's a rising demand for compact multihead weigher systems, especially in small-to-medium enterprises (SMEs).

Why Choose a Multihead Weigher Packing Machine?

ROI-Driven Investment: Though the upfront cost may be significant, the return on investment is quick due to reduced labor, minimal waste, and increased output. Most businesses report full ROI within 1–2 years.

Scalability and Flexibility: From entry-level 10-head models to high-capacity 32-head machines, businesses can choose configurations that match their production scale. Many systems also offer tool-free part swaps, enabling fast product changeovers.

Trusted by Leading Manufacturers: Chinese multihead weigher manufacturers offer customizable systems for different industries. Local suppliers in China's packaging machinery industry also deliver cost-effective and innovative solutions backed by global support networks.

Eco-Friendly Packaging Solutions: Reducing product waste and enabling eco-packaging formats like recyclable pouches or biodegradable film bags helps manufacturers meet sustainability goals.

Choosing the Right Multihead Weigher: Buying Considerations

Product Type and Characteristics: Sticky products may need Teflon-coated surfaces; fragile products benefit from soft-drop mechanisms.

Target Throughput and Accuracy: Choose models that balance speed and precision, suitable for your production volume.

Integration with Other Machines: Ensure compatibility with form-fill-seal machines, bag makers, or secondary packaging equipment.

Local Support and After-Sales Service: Select a multihead weigher manufacturer that offers training, local service centers, and spare part availability.

Conclusion

A multihead weigher packing machine is more than just a weighing tool — it's the centerpiece of modern, automated packaging lines. By ensuring speed, accuracy, and adaptability it helps manufacturers achieve operational excellence and reduce overall costs.

As global demand for pre-packaged products grows, the multihead weigher is a smart, forward-thinking investment that supports both quality and efficiency. Whether you're packaging snacks in a bustling food factory or assembling hardware kits in an industrial setting, a multihead weighing and packing system ensures consistency, compliance, and customer satisfaction.

Tinyeh is one of the multihead weigher packing machine manufacturers in China. Feel free to contact us to get your tailored packing solution.