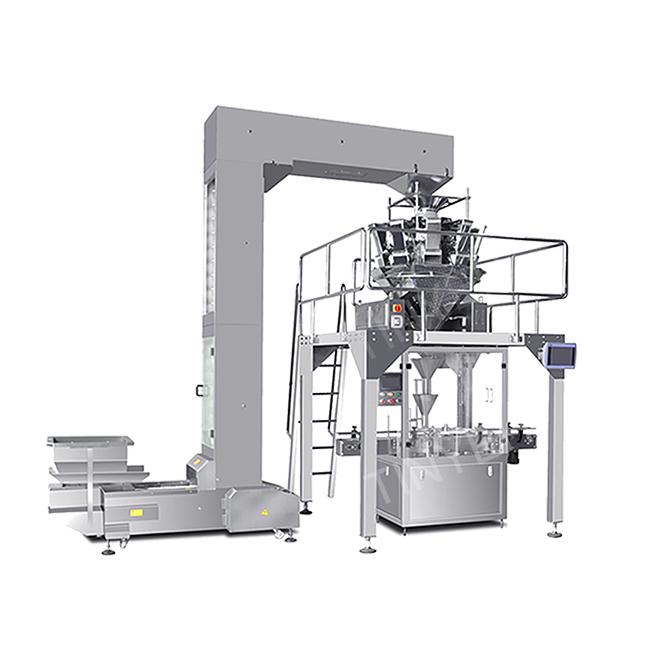

What is a Vertical Rice Packaging Machine?

A Vertical Form-Fill-Seal (VFFS) machine is an automated system designed to package free-flowing granular products like rice. It is called "vertical" because the packaging bag is formed vertically from a roll of plastic film. This all-in-one system performs three core functions:

-

Form: It creates a bag from a roll of packaging material (e.g., polypropylene, laminate).

-

Fill: It precisely measures and dispenses a specific weight of rice into the newly formed bag.

-

Seal: It hermetically seals the top of the bag, ensuring product freshness and preventing contamination.

Key Features and Advantages of Our Rice Packaging Machines

Investing in a modern automatic rice packaging machine offers a significant return on investment through numerous benefits:

-

High-Speed Operation: Capable of packaging dozens of bags per minute, dramatically increasing your output compared to manual labor.

-

Precision Weighing: Integrated with advanced weigh fillers (e.g., linear weigh scales, multi-head weighers) that ensure each bag meets the exact weight requirement, reducing product giveaway and ensuring compliance.

-

Superior Bag Sealing: Produces strong, consistent, and airtight seals that protect the rice from moisture, pests, and spoilage, extending its shelf life.

-

Flexibility in Packaging: Easily adjustable to create various bag sizes and styles, including pillow bags, gusseted bags, and bags with hang holes. Quick changeover allows for different rice varieties (e.g., Basmati, Jasmine, Brown Rice).

-

Reduced Labor Costs: Automates the most labor-intensive part of the packaging process, allowing your staff to focus on quality control and other value-added tasks.

-

Minimized Product Waste: The precision of the system ensures minimal spillage and accurate filling, saving you money on raw materials.

How Does a Vertical Packaging Machine for Rice Work?

The operation of a VFFS machine is a seamless, continuous cycle:

-

Film Feeding: A roll of flat packaging film is mounted on the machine and fed upward.

-

Bag Forming: The film is pulled over a forming tube, where it is shaped into a tube.

-

Vertical Sealing: The longitudinal (vertical) seal is made, creating a continuous tube of film.

-

Cross Sealing & Filling: The top of the bag is cross-sealed. Simultaneously, the pre-measured portion of rice is discharged through the forming tube into the bag.

-

Bag Separation: The filled bag is lowered, the top is sealed, and the finished bag is cut away, ready for cartoning or palletizing.

Applications: More Than Just White Rice

While perfect for standard white rice, our rice bag packaging machines are versatile enough to handle a wide range of products:

-

Basmati, Jasmine, and Arborio Rice

-

Brown Rice and Wild Rice

-

Parboiled Rice

-

Lentils, Beans, and other Pulses

-

Grains like Quinoa and Couscous

-

Seeds and Bird Feed

Choosing the Right Rice Packing Machine for Your Business

When selecting a vertical form fill seal machine, consider these factors:

-

Production Speed: How many bags per minute do you require?

-

Bag Size Range: What are the minimum and maximum bag weights you need to produce?

-

Packaging Material: What type of film will you be using?

-

Weighing System: Choose between a volumetric cup filler for lower accuracy or a linear weigh scale for high precision.

-

Level of Automation: Do you need additional features like an automatic film roll changer, checkweigher, or date coder?