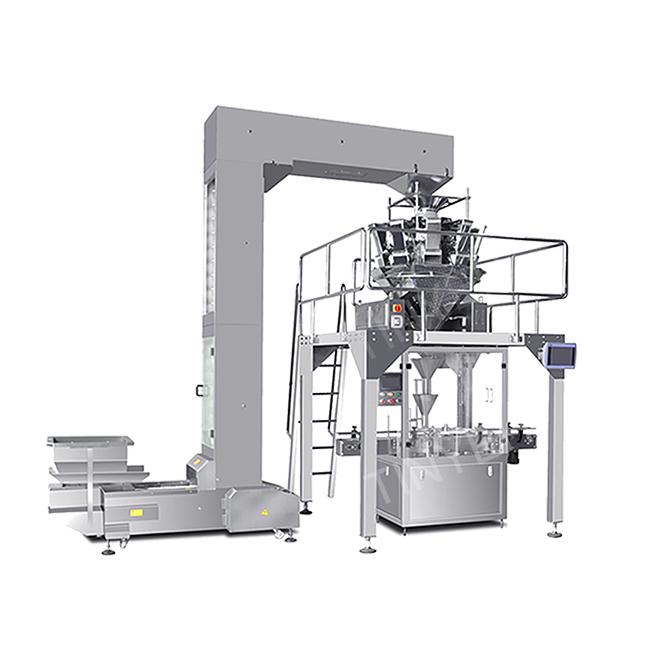

In the world of industrial packaging, efficiently and accurately handling bulky powdered materials is a significant challenge. For industries dealing with products like flour, milk powder, chemicals, starch, and minerals, Vertical Powder Large-Weight Packaging Machines are the indispensable solution. These robust systems are engineered to automate the filling of powders into large bags, typically ranging from 20kg to 50kg (44lbs to 110lbs), ensuring precision, speed, and minimal waste.

This guide explores how these machines work, their key benefits, critical features to consider, and the industries that rely on them.

How Does a Vertical Large-Weight Powder Packager Work?

A vertical packaging machine forms, fills, and seals bags from a roll of film in a continuous vertical motion. For large-weight applications, the process is enhanced for stability and precision:

-

Bag Forming: A roll of packaging film (e.g., PE, PP) is mounted on the machine. The film is drawn downward and formed into a tube shape using a forming collar.

-

Back-Sealing: The longitudinal back seal of the bag is created.

-

Bottom Sealing & Filling: The cross-jaw mechanism seals the bottom of the bag to create a pouch. The product is then dispensed from an overhead hopper into the bag. This is the most critical step for weight accuracy.

-

Weighing and Top Sealing: After filling, the top of the bag is sealed, and the finished bag is released onto a conveyor belt.

The "large-weight" aspect is managed by specialized weighing systems, which we will discuss next.

Key Features of a High-Performance Large-Weight Powder Packager

When selecting a machine, these features are crucial for performance and ROI:

-

High-Precision Weighing System: This is the heart of the machine. Gross/Net Weighing Systems and Weighing Hoppers with high-resolution load cells are used to ensure each bag meets the exact weight target, reducing product giveaway.

-

Auger Filling System: A rotating screw (auger) is the most common method for dispensing powders. It provides excellent control over the flow of material, which is vital for accuracy. The auger and filling spout are often anti-bridging and anti-clogging to prevent blockages.

-

Dust Extraction Port: Powder handling generates dust. Integrated dust collection ports are essential for maintaining a clean working environment, protecting both the product and operators, and ensuring compliance with health regulations.

-

Programmable Logic Controller (PLC) & HMI: A user-friendly touchscreen interface allows operators to easily set parameters like bag length, weight, and production speed. It also provides diagnostic information and production data.

-

Servo Motor Drives: Servo motors provide precise control over the film movement and sealing jaws, resulting in consistent bag quality, reduced film waste, and higher machine reliability.

-

Sturdy Construction: Designed for heavy-duty cycles, these machines are built from high-grade stainless steel and durable components to withstand harsh industrial environments.

Major Benefits for Your Packaging Line

Investing in an automatic vertical powder packager for large weights delivers tangible benefits:

-

Superior Weight Accuracy: Drastically reduces product overfilling and underfilling, saving significant money on raw materials over time.

-

Increased Production Speed: Automates a manual, labor-intensive process, allowing you to package hundreds of bags per hour with minimal operator intervention.

-

Reduced Labor Costs: One machine can replace several manual packing stations, leading to substantial labor savings and reducing the risk of repetitive strain injuries.

-

Enhanced Product Integrity: The sealed bags protect the powder from moisture, contamination, and spoilage, extending shelf life.

-

Improved Workplace Safety & Cleanliness: By containing dust and automating heavy lifting, these machines create a safer and cleaner factory floor.

Industries and Applications

Vertical large-weight powder packaging machines are versatile and used across numerous sectors:

-

Food & Beverage: Flour, sugar, milk powder, protein powder, cocoa, spices, and instant drink mixes.

-

Chemical Industry: Fertilizers, pigments, dyes, plastic compounds, and industrial powders.

-

Pharmaceuticals: Powdered active pharmaceutical ingredients (APIs) and excipients.

-

Building Materials: Cement, gypsum powder, and other construction compounds.

Choosing the Right Machine: Key Considerations

Before purchasing, ask these questions:

-

Product Characteristics: What is the bulk density and flowability of your powder? Is it abrasive or hygroscopic?

-

Required Output: How many bags per minute/hour do you need to produce?

-

Bag Size and Weight: What is your target bag weight (e.g., 25kg, 50kg) and bag dimensions?

-

Level of Automation: Do you need a semi-automatic machine (operator places empty bag) or a fully automatic one?

-

Compliance: Does the machine need to meet specific industry standards (e.g., FDA, USDA, CE)?