In the fast-paced food industry, efficiency and freshness are paramount. For salad producers, vertical packaging machines have become an indispensable tool to meet consumer demands for convenient, high-quality products. These advanced systems not only streamline the packaging process but also ensure that salads remain fresh and appealing from production to consumption.

What is a Vertical Packaging Machine?

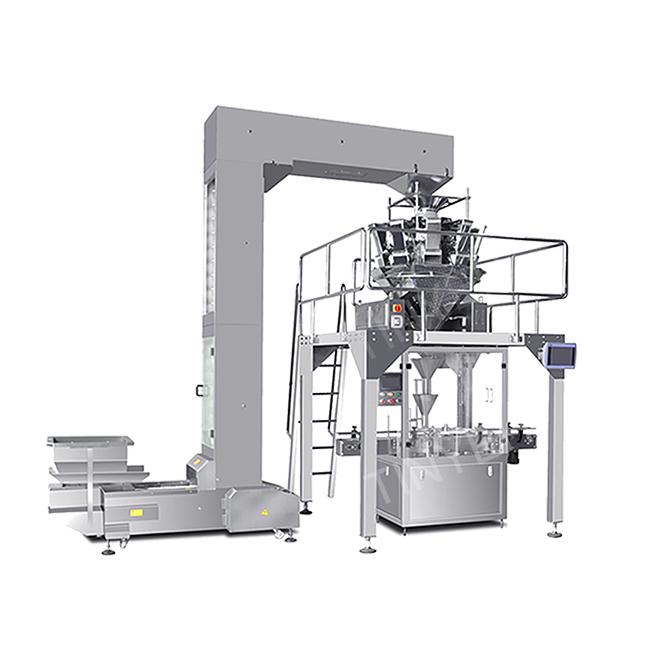

A vertical packaging machine, also known as a form-fill-seal (FFS) machine, is designed to create bags from a roll of film, fill them with product, and seal them in a continuous automated process. Unlike horizontal packaging systems, vertical machines utilize gravity to assist in product loading, making them particularly suitable for free-flowing items like leafy greens, salad kits, and chopped vegetables.

Key Advantages for Salad Packaging

1. Preservation of Freshness

Vertical packaging machines can integrate modified atmosphere packaging (MAP) technology, which replaces the air inside the package with a protective gas mixture. This significantly extends the shelf life of fresh salads by slowing down oxidation and microbial growth.

2. High Efficiency and Speed

Modern vertical packaging systems can achieve impressive speeds of up to 120 bags per minute, allowing producers to meet large-scale demand without compromising on quality. This efficiency is crucial for perishable items that require quick turnaround times.

3. Reduced Material Waste

These machines precisely control film usage, creating tight seals and minimizing material waste. Many models incorporate sustainable practices by supporting recyclable and biodegradable packaging materials.

4. Flexibility in Packaging Design

Vertical packaging machines offer various bag styles including pillow bags, gusseted bags, and stand-up pouches. This flexibility allows brands to create distinctive packaging that stands out on retail shelves while providing convenience to consumers.

How Vertical Packaging Machines Work

The packaging process typically involves four main stages:

-

Film feeding and forming

-

Product filling

-

Sealing

-

Cutting and discharge

Advanced sensors ensure accurate filling weights, while integrated checkweighers guarantee compliance with regulatory requirements. For salad applications, gentle handling systems prevent damage to delicate leaves during the filling process.

Choosing the Right Machine for Salad Packaging

When selecting a vertical packaging machine for salad products, consider these factors:

-

Production capacity requirements

-

Packaging material compatibility

-

Cleanability and sanitation standards

-

Integration capabilities with existing production lines

-

Support for MAP technology

-

Ease of operation and maintenance