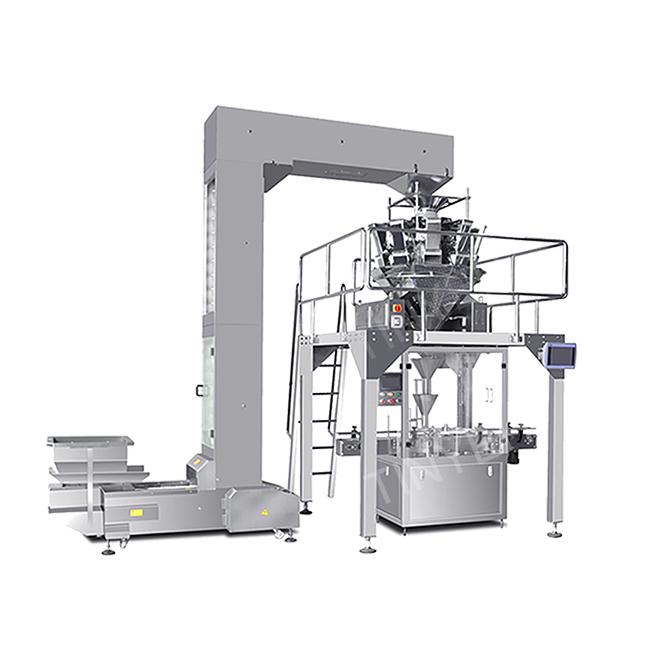

How a Vertical Form-Fill-Seal Machine Works: Core Mechanism Explained

VFFS machines transform flat packaging film into sealed pouches through a synchronized 6-stage process:

1. Film Feeding & Registration

-

Servo-driven rollers unwind pre-printed film from the reel

-

Photoelectric sensors align registration marks (critical for printed packaging) within ±0.2mm accuracy

2. Tube Formation

-

Collar-style forming shoulder shapes flat film into a vertical tube

-

Adjustable guides accommodate pouch widths from 30mm to 450mm

3. Vertical Sealing

-

Heated jaws create continuous longitudinal seals at 120-200°C (material-dependent)

-

Advanced models feature dual-seal systems for moisture-sensitive products

4. Product Dispensing

-

Volumetric augers (for granules) or liquid pumps (for fluids) fill pre-measured doses

-

Multi-head weighers achieve ±0.3% dosing accuracy in food/pharma applications

5. Horizontal Sealing & Cutting

-

Reciprocating cross jaws simultaneously seal and separate pouches

-

Pulse sealing technology prevents film scorching (cycle time: 0.8-2.5 seconds)

6. Quality Assurance

-

Integrated checkweighers and vision systems reject non-compliant packages

-

Real-time OEE (Overall Equipment Effectiveness) monitoring via HMI interfaces

5 Proven Optimization Strategies for VFFS Machines

1. Precision Parameter Tuning

-

Temperature Control: Calibrate sealing jaws using IR thermometers (Ideal range: LDPE 120-150°C, PET/AL 160-200°C)

-

Speed Synchronization: Match film feed rate to product discharge (Formula: Pouch length ÷ Cycle time = Film speed)

-

Film Tension Adjustment: Maintain 15-25N tension via load cells to prevent wrinkling/tearing

2. Maintenance Protocols

-

Daily: Clean sealing surfaces with silicone-coated wipes

-

Weekly: Lubricate chain drives with food-grade grease (NSF H1 certified)

-

Monthly: Validate sensor calibration using ISO 2859 sampling plans

3. Film Waste Reduction Tactics

-

Use edge-trim recycling systems (saves 8-12% material costs)

-

Implement servo-assisted registration (reduces setup waste by 40%)

4. Energy Efficiency Upgrades

-

Replace conventional heaters with ceramic IR elements (30% energy savings)

-

Install variable frequency drives (VFDs) on main motors

5. Smart Technology Integration

-

Retrofit IoT sensors for predictive maintenance (vibration analysis, thermal imaging)

-

Connect to MES systems for batch traceability (critical for FDA 21 CFR Part 11 compliance)

Industry-Specific Configuration Tips

| Application | Key Settings |

|---|---|

| Coffee Beans | Gas flushing (99.9% N₂), 3-side seals |

| Pharmaceutical Powders | Dust-proof augers, CIP/SIP compatibility |

| Hygienic Wipes | Perforation units, ultrasonic sealing |

(Table format improves mobile readability and featured snippet chances)

Why Optimization Matters

Properly tuned VFFS machines can achieve:

-

99% uptime through preventive maintenance

-

15-25% higher output via speed optimization

-

50% reduction in packaging material waste