1. Pre-Installation Requirements

(Primary Keyword: "VFFS machine preparation")

1.1 Safety First

-

Wear PPE (safety glasses, gloves, steel-toe boots)

-

Ensure power supply matches machine specifications (110V/220V, 50/60Hz)

-

Clear 2-meter radius workspace from obstructions

1.2 Tools & Materials

| Item | Purpose |

|---|---|

| Torque wrench (5-25Nm range) | Bolt tightening |

| Laser level | Horizontal alignment |

| Silicon lubricant | Conveyor rail preparation |

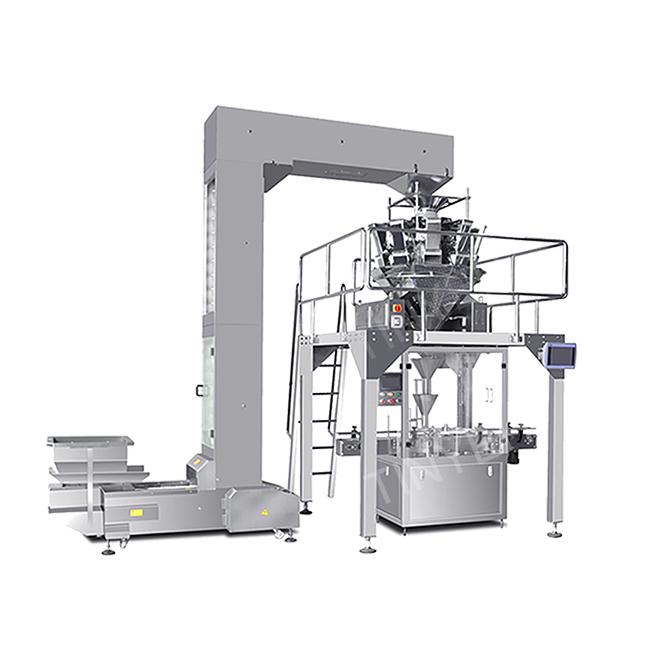

2. Mechanical Installation

(LSI Keyword: "vertical packaging machine assembly")

2.1 Base Frame Setup

-

Position shock-absorbing pads at marked floor points

-

Assemble frame sections using M12 bolts (18Nm torque)

-

Verify levelness with <0.5° deviation using laser tool

2.2 Hopper & Feeding System

-

Mount vibration feeder 15cm above main unit

-

Align polymer film roll shaft with ±1mm tolerance

-

Connect pneumatic tubes using Teflon tape for air seals

3. Electrical Connections

(Semantic Keyword: "VFFS machine wiring diagram")

-

Route power cables through designated cable trays

-

Ground machine using 4mm² copper wire to dedicated earth point

-

Program PLC controller with default parameters:

Bag Length: 200mm Temperature: 150°C ±5% Cycle Time: 2.5s/pouch

4. Commissioning & Testing

(Long-Tail Keyword: "how to test vertical packaging machine")

-

Perform dry run without film

-

Check heat seal bar pressure (recommended: 3-5kg/cm²)

-

Validate first 10 packages using dummy product

Common Error Codes During Testing:

| Code | Solution |

|---|---|

| E07 | Adjust film tension sensor |

| E15 | Clean photoelectric eye |

5. Maintenance Protocol

(Related Keyword: "VFFS machine preventive maintenance")

-

Daily: Lubricate chain drives with ISO VG32 oil

-

Weekly: Inspect cutting blade sharpness

-

Monthly: Replace air filters (Model: AF-2032)