Automatic filling machines have become indispensable tools for industries ranging from food and pharmaceuticals to chemicals and cosmetics. Among these, powder, liquid, and granule filling machines stand out as essential packaging solutions for diverse production needs.

Tinyeh offers innovative solutions for each of these filling needs, delivering machines that ensure high efficiency, accuracy, and adaptability. These machines can operate independently or be linked together for streamlined production workflows.

1. Automatic Powder Filling Machines

Powder filling machines are essential for packaging powdered materials with precision. They are widely used in industries such as pharmaceuticals, food production, chemicals, and cosmetics.

Automatic Powder Filling Machine Suitable For Cans, Bottles, and Tins

Advantages of Powder Filling Machines

Powder filling machines are engineered to deliver precise, consistent filling for powdered products in a variety of industries. They ensure efficiency, reduce waste, and maintain product quality.

High Precision Filling: Advanced screw feeding or piston pump systems provide accurate dosage for different powder types.

Adaptable to Material Properties: Can handle fine powders, coarse powders, and mixed powders with varying densities.

Hygienic and Durable Design: Stainless steel construction meets GMP standards and allows easy cleaning to prevent contamination.

Operational Efficiency: Automated controls and intuitive interfaces simplify operation and reduce human error.

Versatile Integration: Can work as standalone units or integrate into automated production lines.

Applications

Pharmaceutical powders (e.g., medicinal tablets and supplements)

Food powders (e.g., protein powder, flour, spices)

Chemical powders (e.g., detergents, additives)

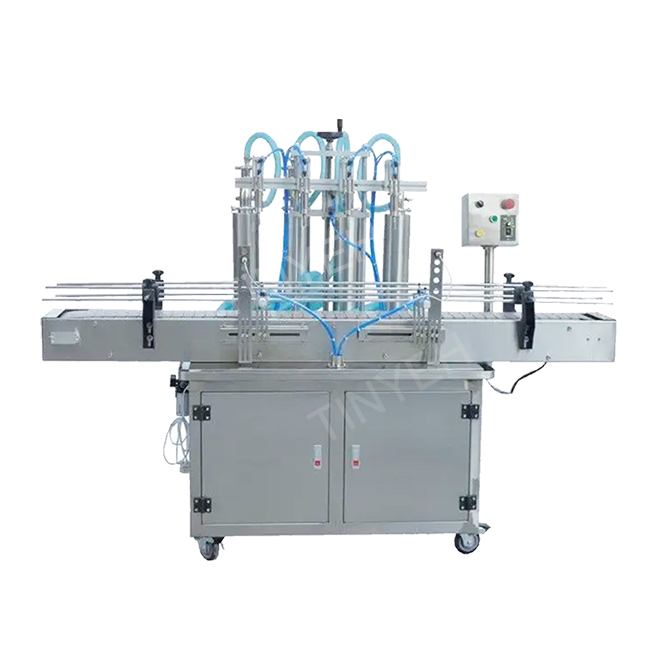

2. Automatic Liquid Filling Machines

Liquid filling machines are designed to handle various liquids with precision, ensuring consistent quality for products like beverages, sauces, cosmetics, and chemicals.

Automatic Piston Liquid Juice Oil Honey Filling Machine

Advantages of Liquid Filling Machines

Liquid filling machines are designed for accuracy and adaptability, making them suitable for diverse liquid packaging needs, from thin solutions to high-viscosity fluids.

Wide Range of Applications: Compatible with water-like liquids, creams, oils, and liquids with suspended particles.

Accurate Volume Control: Peristaltic or piston filling systems ensure consistent fill volumes for every container.

Easy Operation: PLC touch screen systems enable quick recipe switching and real-time monitoring.

Hygienic Construction: Stainless steel parts and sanitary design support easy cleaning and compliance with hygiene standards.

Energy and Space Efficient: Compact design with optimized pump systems reduces operational costs.

Applications

Food and beverage liquids (e.g., sauces, juice, dairy products)

Cosmetics (e.g., creams, lotions)

Chemical liquids (e.g., detergents, oils)

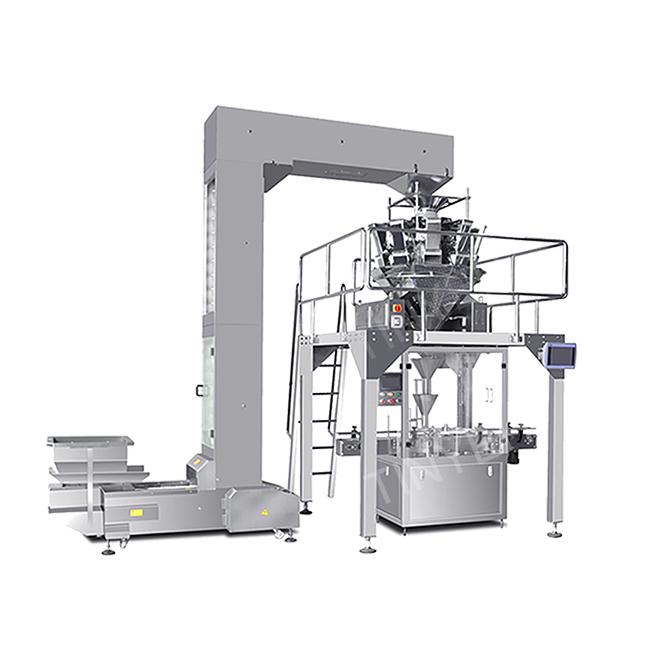

3. Automatic Granule Filling Machines

Granule filling machines are perfect for packaging products in granular form, ensuring precise filling without material spillage or waste. They are widely used in food, agriculture, and pharmaceutical industries.

Automatic Granule Grain Solid Bottles Cans And Tins Filling Line

Advantages of Granule Filling Machines

Granule filling machines are ideal for high-speed, accurate packaging of granular materials while minimizing product loss and contamination risk.

Precise Filling Mechanisms: Screw feeders or volumetric cups ensure consistent measurements for granular products.

Material Preservation: Gentle filling processes maintain granule integrity, avoiding crushing or dust generation.

High Efficiency: Fast operation suitable for high-volume production without compromising accuracy.

Easy Maintenance: Modular design allows quick cleaning and part replacement to maximize uptime.

Flexible Operation: Can operate independently or as part of integrated packaging systems.

Applications

Food granules (e.g., sugar, salt, rice)

Pharmaceutical granules

Agricultural products (e.g., seeds, fertilizers)

Industries Benefiting from Automatic Filling Machines

Automatic filling machines cater to a wide range of industries, providing efficiency and accuracy in packaging processes:

Food Industry: For powders (flour, protein), liquids (juice, sauces), and granules (sugar, rice).

Pharmaceutical Industry: For tablets, medicinal powders, liquid medicines, and supplements.

Cosmetic Industry: For creams, lotions, and liquid soaps.

Chemical Industry: For detergents, liquid chemicals, and granular chemicals.

Agricultural Industry: For packaging seeds, fertilizers, and feed granules.

Choosing the Right Filling Machine for Your Business

Choosing the right filling machine is a critical decision for manufacturers, as it directly impacts production efficiency, product quality, and overall cost-effectiveness. Different industries and materials have unique requirements, so careful consideration is essential to ensure optimal performance and long-term benefits.

Here are the key factors to consider when selecting a filling machine:

1. Material Type and Properties

The type of material you are packaging—whether powder, liquid, or granule—will determine the most suitable filling system.

Powders require machines with accurate metering systems such as screw feeders or piston pumps, capable of handling fine powders, coarse powders, and mixed formulations.

Liquids need filling machines with peristaltic pumps or piston fillers that can accommodate thin fluids, high-viscosity liquids, or liquids containing particles.

Granules require screw feeding or volumetric cup systems to ensure precise measurement without damaging the product.

2. Production Volume and Speed

Evaluate your production needs. For high-volume operations, high-speed automatic filling machines with integration capabilities will save time and labor costs. Low-volume or specialty product runs might be better suited to flexible machines that can quickly adjust filling volumes without significant downtime.

3. Accuracy and Consistency

Precision is critical, especially for pharmaceuticals, food supplements, or high-value products. Machines with advanced control systems and precise measurement mechanisms ensure consistent product fill weights and volumes, reducing waste and maintaining quality.

4. Hygienic Requirements

For industries like food, pharmaceuticals, and cosmetics, compliance with hygiene standards such as GMP is essential. Machines made of 304 stainless steel, with easy-to-clean designs, help prevent contamination and simplify sanitation processes.

5. Flexibility and Integration

Consider whether the machine will operate independently or as part of a larger packaging line. Some filling machines are designed for standalone use, while others can be integrated with capping, labeling, and packaging systems for fully automated production. Flexibility in operation can enhance productivity and scalability.

6. Budget and ROI

While the initial investment is important, consider the long-term return on investment. A higher-quality filling machine with lower maintenance needs and better accuracy will save costs over time, especially in large-scale production environments.

7. Technical Support and Maintenance

Choosing a machine with reliable technical service and easy access to spare parts can reduce downtime and ensure smooth operation throughout the machine's service life.

When selecting a filling machine, it is helpful to consult with professional equipment suppliers, provide detailed specifications about your product, and request machine demonstrations or trials. It ensures the chosen machine aligns with your production requirements and quality standards.

Comprehensive Packaging Solutions with Advanced Filling Machines

Tinyeh provides a range of high-quality filling machines designed to meet diverse packaging needs across various industries. These include powder filling machines, liquid filling machines, and granule filling machines, offering complete solutions for efficient and accurate packaging.

✅ Versatile Application: Suitable for industries such as food, pharmaceuticals, cosmetics, and chemicals, providing packaging solutions for powders, liquids, and granules.

✅ Flexible Operation: Each machine can operate independently as a single unit or be linked into a fully integrated packaging line, offering adaptability for both small-scale and high-volume production.

✅ Advanced PLC Control: Equipped with PLC control systems and intuitive touchscreen operation, making setup and recipe adjustments simple, reducing downtime, and enhancing productivity.

✅ Reliable Performance: Uses premium electrical components from internationally recognized brands to ensure consistent, stable performance and long-term durability.

✅ Hygienic and Durable Design: Made with 304 stainless steel to meet GMP compliance requirements, ensuring easy cleaning and maintaining high hygiene standards.

✅ Precise Filling Systems: Incorporates peristaltic pumps or piston pumps for accurate measurement and controlled filling, reducing waste and ensuring consistent product quality.

By offering these advanced features, Tinyeh's filling machines deliver a dependable, flexible, and efficient solution for a wide range of packaging needs.

Conclusion

Automatic filling machines have become essential in modern manufacturing, enabling high-speed production without compromising accuracy or hygiene. Tinyeh's powder, liquid, and granule filling machines deliver innovative packaging solutions that adapt to diverse industrial needs. Whether working independently or linked as part of a full production line, these machines offer unmatched reliability and precision.

With advanced control systems, durable stainless steel construction, and GMP compliance, Tinyeh filling machines ensure both productivity and quality assurance. By choosing Tinyeh, you gain not only a machine but a partner in packaging excellence. Browse our automatic filling machine for more.