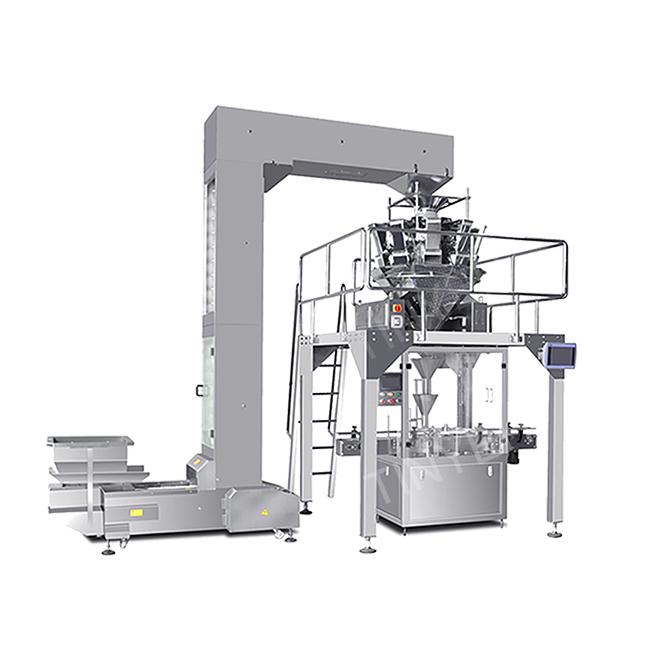

In the dynamic world of food packaging, efficiency, hygiene, and product integrity are paramount. For producers of macaroni, penne, fusilli, and other short-cut pasta, the vertical form-fill-seal (VFFS) packaging machine stands as a cornerstone of modern production lines. This sophisticated equipment seamlessly transforms rolls of packaging film into filled and sealed bags of pasta, offering unparalleled speed and consistency.

Core Principle: How It Works

The vertical packaging machine operates on a brilliantly efficient principle. It is a continuous motion system where the package is formed around the product itself. The process can be broken down into four key stages:

-

Film Unwinding & Forming: A roll of flat packaging film (such as polypropylene or laminated materials) is mounted on the machine. The film is fed upward and guided through a tensioning system into a "forming tube." As the film is pulled down over this tube, it is shaped into a continuous vertical cylinder.

-

Back Sealing & Filling: The vertical edges of the film are sealed together by a longitudinal sealer, creating a sturdy back fin seal. This forms a continuous tube. At the top of this tube, the measured portion of pasta is dropped through the forming tube and into the waiting bag below. This gravity-fed system is ideal for free-flowing products like dry pasta.

-

Cross Sealing & Separation: Below the forming tube, two heated horizontal jaws close simultaneously. They perform two critical functions: they seal the top of the filled bag and the bottom of the next bag-to-be in a single motion. A cross-cutting knife then separates the two, releasing a finished, sealed package.

-

Discharge: The completed bag is discharged via a conveyor belt to the next station, which could be for check-weighing, labeling, or case packing.

Key Advantages for Pasta Packaging

The adoption of vertical packaging machines in the pasta industry is driven by a host of significant benefits:

-

High Efficiency and Speed: VFFS machines are capable of extremely high output, often reaching speeds of over 100 bags per minute, making them ideal for meeting large-scale production demands.

-

Reduced Material Waste: Using rolls of flat film is far more material-efficient than using pre-made bags. This minimizes waste and reduces packaging costs.

-

Flexibility: With a quick change of the forming tube and the film reel, the same machine can produce bags of various sizes and shapes. This allows producers to easily switch between different pasta types or package weights.

-

Excellent Product Preservation: These machines can be integrated with nitrogen gas flushing systems. By displacing oxygen inside the bag before sealing, the shelf life of the pasta is significantly extended, protecting it from oxidation and spoilage.

-

Hygienic Design: Modern vertical packagers are constructed with food-grade stainless steel and feature smooth surfaces that are easy to clean and sanitize, ensuring compliance with strict food safety standards.

-

Space Optimization: As the name implies, the vertical design has a small footprint, conserving valuable floor space in the production facility.

Essential Features for Optimal Performance

To handle the specific challenges of pasta, which can be abrasive and fragile, these machines are often equipped with specialized features:

-

Auger Filling System: For precise weighing and gentle handling of pasta, a auger filler is often used. It screws the product into the bag, ensuring accurate portion control and minimizing breakage.

-

Robust Sealing Jaws: Consistent, strong seals are critical. High-quality machines feature durable sealing jaws that can maintain the correct temperature and pressure to create a hermetic seal through any potential dust or fine particles from the pasta.

-

Advanced Control System: A user-friendly PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) allow operators to easily set parameters, monitor performance, and diagnose issues, ensuring smooth operation.

-

Integrated Checkweigher: Many lines include an inline checkweigher that rejects any under or over-weight bags, guaranteeing product consistency and compliance with regulatory standards.