When it comes to producing and selling popsicles, the packaging process plays a much bigger role than many first realize. A popsicle packaging machine doesn't just wrap frozen treats—it protects texture, maintains hygiene, and gives the final product its commercial appeal. Whether you're a small-scale startup experimenting with new flavors or an established ice cream factory upgrading your production line, choosing the right popsicle packaging equipment can dramatically influence your efficiency, quality, and profit margins.

Below, we'll take a detailed look at the types of popsicle packaging machines on the market, their key features, price ranges, and the practical factors that should guide your purchase decision.

1. Understanding Popsicle Packaging Machines

At their core, popsicle packaging machines are designed to automatically wrap frozen products—typically in plastic film or composite material—sealing them quickly and hygienically. The goal is simple: preserve freshness, prevent melting during handling, and create a consistent, market-ready presentation.

Modern packaging lines integrate several components:

● Feeding system – Aligns popsicles for consistent entry.

● Film unwinding system – Controls wrapping material tension.

● Sealing and cutting units – Apply heat to seal ends and separate packages.

● Cooling conveyors – Maintain low temperatures after sealing.

Machines differ in automation level, packaging style, and capacity. The right fit depends heavily on your production volume and desired packaging appearance.

2. Types of Popsicle Packaging Machines

a. Horizontal Flow Wrap Machines

The most common model for ice pops and ice cream bars, horizontal flow wrappers feed products horizontally through a sealing jaw that wraps each popsicle individually. These are ideal for mid to large-scale producers. Popular in industrial ice cream lines, these machines can handle 100–600 popsicles per minute, depending on configuration.

b. Vertical Form Fill Seal (VFFS) Machines

Although less common for rigid popsicles, VFFS systems are used for soft or tube-style popsicles (like freeze pops or ice lollies). They form bags from a roll of film, fill them with liquid, then seal and cut them—perfect for mass production of frozen liquid treats.

c. Semi-Automatic Popsicle Wrappers

These machines are often chosen by small workshops or regional dessert makers. They require some manual handling, such as feeding or film adjustment, but they're budget-friendly and easy to maintain. A semi-automatic popsicle wrapping machine can cost one-tenth the price of a full industrial system.

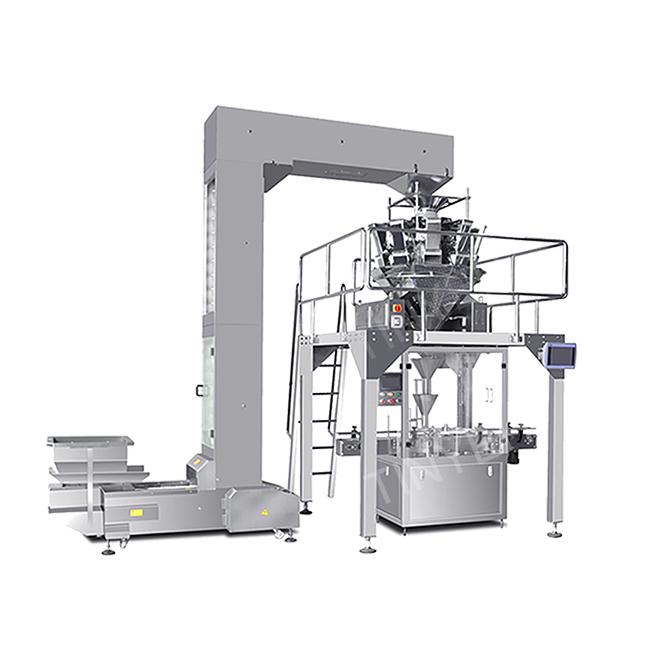

d. Fully Automatic Multi-Row Packaging Systems

Designed for continuous, high-speed production lines. These systems integrate counting, feeding, wrapping, and labeling functions. You'll often see them in factories producing for brands like Nestlé or Unilever. Some advanced models can even synchronize with stick inserters, flow wrappers, and cartoning machines.

3. Key Features of Popsicle Packaging Machines to Look For

Choosing a popsicle packaging machine isn't just about speed. Consider these features carefully before purchasing:

Material Compatibility: Make sure your machine supports the right packaging materials—commonly OPP, PE, or laminated films. Eco-conscious manufacturers may prefer biodegradable or recyclable films, and not all sealers handle them equally well.

Temperature Control: Because popsicles are sensitive to heat, sealing must happen precisely. Advanced models offer intelligent temperature control systems that ensure stable sealing without melting the product edges.

Hygienic Design: Look for stainless steel construction (usually SUS304 or SUS316), smooth welds, and easy-to-clean surfaces. This is essential for meeting HACCP or ISO22000 food safety standards.

Servo Motor and PLC Control: A servo-driven popsicle packaging machine ensures precise positioning and reduced film waste. PLC touchscreen interfaces also make adjustments easier and allow for multi-product setups.

Integration and Automation: If your production line already includes a popsicle-making machine, choose a packaging machine that can integrate seamlessly. Some manufacturers, such as Foshan Dession Machinery or Shanghai Joygoal Machinery, offer customizable automation systems linking filling, freezing, and packaging together.

Film Printing and Labeling Options: Modern packaging machines can include date coders, barcode printers, or label applicators directly within the line—cutting down on separate labeling processes.

4. Price Range and Budget Planning

Prices for popsicle packaging machines vary widely based on capacity, technology, and level of automation. Here's a general breakdown:

| Machine Type | Capacity (pcs/min) | Price Range (USD) | Ideal For |

| Semi-Automatic Wrapper | 30–60 | $2,000–$6,000 | Small shops, start-ups |

| Horizontal Flow Wrapper | 100–400 | $8,000–$25,000 | Medium-sized producers |

| High-Speed Servo Flow Wrapper | 400–600 | $25,000–$60,000 | Industrial operations |

| Fully Integrated Line (with feeding & labeling) | 800+ | $70,000–$150,000+ | Large-scale manufacturers |

Additional costs may include spare parts, training, or customized mold setups for different popsicle shapes. When budgeting, also account for packaging material and cooling system integration.

5. Choosing the Right Manufacturer

When comparing manufacturers, don't just look at the price tag. Evaluate service reliability, after-sales support, spare parts availability, and machine warranty.

Tinyeh is one of the top popsicle packaging machine manufacturers, offering:

Super manufacturer: With a workshop of 10,000 square meters and a professional team of engineers, the total number of designs is up to 500.

Efficient customization service: A Professional engineering team will provide a CAD design plan within 1 hour upon request.

Good Services: We can provide 24-hour online after-sales service, equipment with 36 36-month free warranty.

High Quality: The machine is made of 304 stainless steel plate. A fatigue test will be carried out for 1 week before each device is shipped.

6. Real-World Applications and Use Cases

A growing number of small food businesses are using compact popsicle packaging machines to diversify their offerings. For example, boutique dessert cafes or farm-to-freezer brands package handcrafted fruit popsicles in custom-branded biodegradable film to appeal to eco-conscious consumers.

Meanwhile, industrial ice cream plants rely on high-speed lines that can pack multiple flavors and shapes simultaneously, from twin-stick ice lollies to chocolate-coated bars. The flexibility of modern flow wrappers allows for fast product changeovers—critical during peak summer months when demand surges.

7. Maintenance and Long-Term Efficiency

Regular maintenance ensures longevity and stable performance. Lubricate moving parts, replace sealing blades periodically, and clean the film feeding path after each shift. Many modern models feature self-diagnostic systems that alert operators to motor faults or temperature inconsistencies.

For facilities running multiple shifts, investing in a servo-driven automatic popsicle packaging machine with remote monitoring capabilities can significantly reduce downtime and maintenance costs.

Conclusion

Choosing the right popsicle packaging machine is a balance of speed, precision, and practicality. Small producers should focus on ease of use and affordability, while larger factories benefit from fully automated systems that integrate seamlessly into existing production lines.

When evaluating models, prioritize temperature control, hygiene design, and compatibility with eco-friendly films. Don't forget after-sales support and spare part availability—because a machine that's efficient on paper but unreliable in practice can quickly melt your profits.

Whether you're crafting artisanal fruit pops or managing a high-capacity ice cream bar factory, the right packaging machine can make all the difference between surviving the heat and owning the summer market.