In today’s fast-paced food manufacturing industry, efficiency, hygiene, and consistency are paramount. Peanut butter packaging machines have become essential equipment for peanut butter producers looking to streamline their operations, improve packaging quality, and meet growing market demands. Whether for small-scale businesses or industrial-scale production, these machines significantly enhance convenience, reduce labor costs, and ensure packaging precision.

Why Peanut Butter Packaging Machines Matter?

Manual packaging of peanut butter is not only time-consuming but also prone to inconsistency, contamination, and product waste. Automated peanut butter packaging machines solve these issues by delivering precise fills, clean seals, and rapid throughput. They are specifically designed to handle the thick, sticky consistency of peanut butter and other viscous spreads, making them ideal for a variety of packaging formats such as jars, sachets, pouches, and bottles.

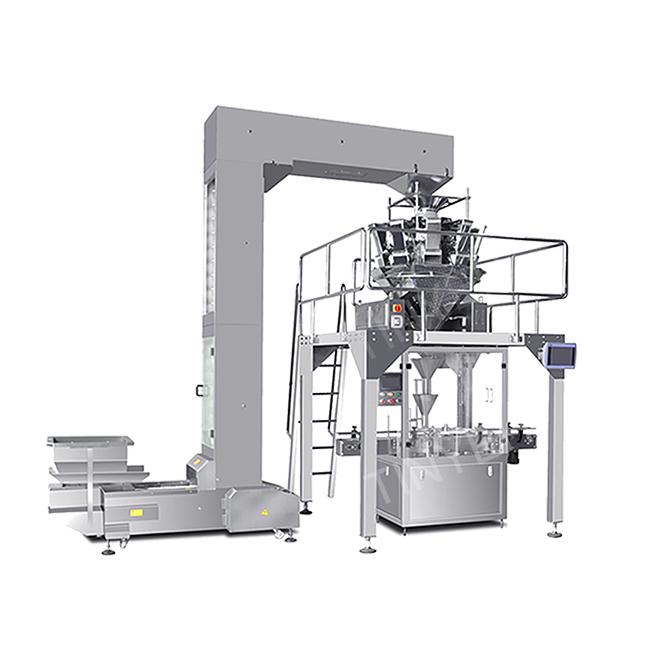

High Speed Peanut Butter Packaging Machines

Types of Peanut Butter Packaging Machines

When investing in a peanut butter packing machine, it’s crucial to choose the right type based on production needs:

Jar Filling Machines – Perfect for filling glass or plastic jars with peanut butter. These machines can be semi-automatic or fully automatic, depending on production volume.

Pouch Packing Machines – Ideal for flexible packaging formats, these machines form, fill, and seal peanut butter in food-grade pouches.

Bottle Filling Machines – Used for filling peanut butter into squeeze bottles, which are gaining popularity in retail markets.

Vacuum Packaging Machines – Extend shelf life by removing air and sealing peanut butter in airtight packs.

Each machine is customizable based on the viscosity of the product, fill volume, container type, and output requirement.

Key Benefits of Using Peanut Butter Packaging Equipment

1. Improved Efficiency: Modern peanut butter packaging machines are capable of filling and sealing hundreds or even thousands of units per hour. This boosts productivity and reduces manual labor dependency.

2. Enhanced Hygiene and Safety: Automated systems minimize human contact with the product, significantly reducing contamination risks. Stainless steel construction and CIP (Clean-in-Place) functions also meet the strict hygiene standards of the food industry.

3. Consistent Filling Accuracy: Thanks to servo-driven technology and precision dosing systems, these machines ensure uniform fill levels in every container. This reduces overfilling and product waste, saving money in the long run.

4. Customization and Versatility: Whether you're packaging creamy or chunky peanut butter, the machines can be fine-tuned to match different textures. Multi-head fillers and dual-nozzle systems also allow for dual-flavor or layered packaging.

5. Cost-Effective Production: Though the initial investment in peanut butter packaging machines may seem high, the long-term benefits outweigh the costs. Reduced labor, minimized waste, and faster output all contribute to higher ROI.

Choosing the Right Peanut Butter Packing Machine Supplier

Selecting a reliable peanut butter packaging machine manufacturer is crucial for long-term success. Look for a supplier with a proven track record in food-grade machinery, offers customization services, provides after-sales support, and complies with international safety standards such as CE and ISO.

When comparing peanut butter packaging machine prices, consider factors like:

● Automation level (manual, semi-auto, or full-auto)

● Output speed (units/hour)

● Packaging type and size range

● Power consumption

● Maintenance and spare parts availability

A good supplier will help you evaluate your production goals and recommend the best peanut butter filling and sealing machine tailored to your needs.

Applications Beyond Peanut Butter

While optimized for peanut butter, these packaging machines are often suitable for other viscous products such as:

● Almond butter

● Tahini

● Chocolate spreads

● Jam and jelly

● Honey

● Mayonnaise

● Ketchup

This versatility adds further value to your investment.

How Peanut Butter Packaging Machines Drive Sales?

From an e-commerce and retail standpoint, visually appealing and leak-proof packaging builds customer trust and brand image. With high-quality packaging ensured by automated machines, your peanut butter products can better compete on store shelves and online platforms.

Additionally, efficient packaging machinery enables you to respond to large purchase orders, private labeling requests, and export opportunities, helping to grow your business globally.

Conclusion

Investing in a peanut butter packaging machine is a smart move for any business involved in food production and packaging. With its ability to improve convenience, accuracy, and productivity while ensuring product safety, this equipment is a game-changer for manufacturers aiming to scale their operations and meet modern consumer demands.

Looking for sachet paste packing machine manufacturers? As a packaging machine factory in China, Tinyeh provides various types of vertical packaging machines, including those specifically designed for liquids and pastes. We offer a range of machines tailored for different viscosities, ensuring optimal performance in filling and sealing operations. By selecting reputable peanut butter packaging machine manufacturers like Tinyeh, you can ensure you acquire reliable machinery that meets your specific packaging needs.