In today's fast-paced manufacturing landscape, efficiency, precision, and reliability are non-negotiable. For businesses packaging granular products, powders, liquids, solids, snacks, and countless other items, High-Speed Vertical Form Fill Seal (VFFS) Machines stand as the cornerstone of modern automated packaging lines. These sophisticated systems are engineered to deliver unmatched productivity, consistency, and cost-effectiveness.

What is a High-Speed Vertical Packaging Machine?

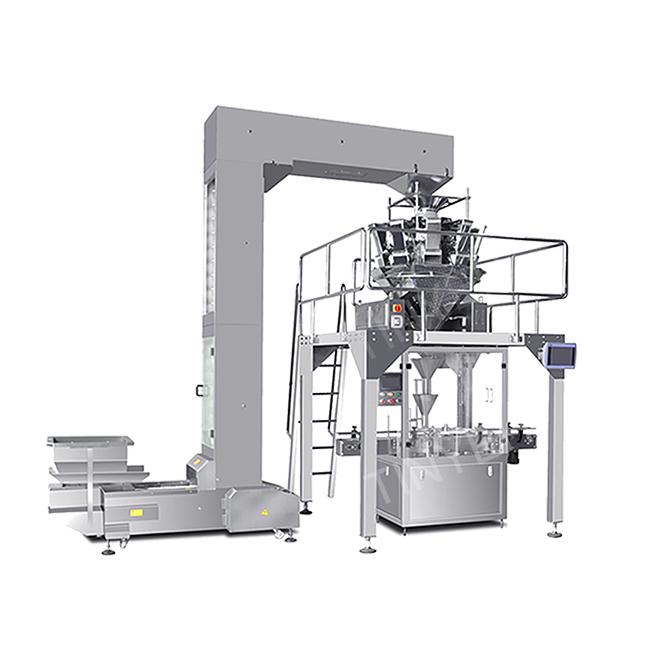

A VFFS machine is an automated packaging system that performs three critical functions in one continuous, vertical motion:

-

Form: Creates a bag from a flat roll of flexible packaging film (polyethylene, laminates, foil, etc.).

-

Fill: Precisely doses the product into the newly formed bag.

-

Seal: Seals the filled bag top and bottom (or side, depending on configuration), creating a finished, hermetic pouch.

"High-Speed" specifically refers to VFFS machines optimized for maximum output, typically ranging from 60 to over 200 bags per minute, depending on bag size, product characteristics, and machine configuration.

Key Features & Technological Advancements:

Modern high-speed VFFS machines incorporate cutting-edge technology to achieve peak performance:

-

Ultra-Precise Servo Drives: Replace mechanical systems, offering exceptional control over film movement, positioning, and sealing. This ensures minimal film waste, perfect bag registration, and enables quick changeovers.

-

Advanced PLC Control & Touchscreen HMIs: Intuitive interfaces allow for easy recipe management, real-time monitoring of production data (speed, counts, waste), diagnostics, and remote support capabilities.

-

Robust Film Handling Systems: Ensure smooth, consistent feeding of diverse film types (including challenging laminates and pre-printed films), minimizing jams and wrinkles critical at high speeds.

-

High-Accuracy Multi-Head Weighers or Auger Fillers: Integrated with the machine for precise, high-speed product dosing – the key to maintaining overall line speed.

-

Sophisticated Sealing Technology: Dual or triple sealing jaws with precise temperature and pressure control guarantee strong, consistent, and hermetic seals on various materials, even at rapid cycles.

-

Enhanced Hygienic Design (EHEDG/ASME BPE compliant): Essential for food, pharmaceutical, and chemical applications, featuring easy-clean surfaces, minimal crevices, and often CIP/SIP capabilities.

-

Industry 4.0 Connectivity: Integration with plant networks (OPC UA, MQTT) for data collection (OEE monitoring), predictive maintenance alerts, and seamless line integration.

-

Versatile Tooling: Quick-change bag forming collars and sealing jaws facilitate rapid transitions between different bag styles and sizes.

Primary Applications & Industries:

High-speed VFFS machines are indispensable across numerous sectors:

-

Food & Beverage: Snacks (chips, nuts, candies), frozen foods, coffee, tea, sugar, flour, grains, pasta, spices, powdered drinks, pet food.

-

Pharmaceuticals: Powders, granules, capsules, tablets, medical devices.

-

Chemicals & Detergents: Granular detergents, pool chemicals, agricultural products, industrial powders.

-

Hardware & DIY: Screws, nails, fasteners, seeds, small parts.

-

Cosmetics & Personal Care: Bath salts, powders, creams (in stick packs or sachets).

Benefits Driving Adoption:

-

Unmatched Productivity: Significantly higher output rates compared to semi-automatic or standard VFFS machines, maximizing ROI.

-

Superior Product Integrity & Freshness: Consistent hermetic seals protect product quality, extend shelf life, and prevent contamination.

-

Reduced Operating Costs: Automation minimizes labor requirements. Precise film control and reduced giveaway lower material costs.

-

Enhanced Flexibility: Ability to handle diverse products and numerous bag styles (stand-up pouches (SUP), pillow bags, gusseted bags, quad-seal bags, Doypacks, stick packs) on a single platform.

-

Exceptional Accuracy: Precise filling and consistent bag dimensions ensure product weight compliance and attractive presentation.

-

Improved Sustainability: Optimized film usage and reduced waste contribute to environmental goals.

-

Robust Reliability: Engineered for continuous 24/7 operation in demanding industrial environments, minimizing downtime.

Choosing the Right High-Speed VFFS Machine:

Consider these critical factors:

-

Product Characteristics: Size, shape, flowability, abrasiveness, temperature, hygiene requirements.

-

Required Output Speed: Target bags per minute (BPM).

-

Bag Specifications: Type (SUP, pillow, etc.), size range, film material, printing requirements.

-

Filling System: Volumetric auger, multi-head weigher, liquid filler – must match product and speed.

-

Sealing Needs: Type of seal (fin seal, lap seal), material thickness, potential for gas flushing (MAP).

-

Integration Level: Compatibility with upstream feeders and downstream equipment (case packers, cartoners).

-

Hygiene & Safety Standards: Necessary certifications (CE, UL, EHEDG, FDA, GMP).

-

Supplier Reputation & Support: Proven track record, quality engineering, global service network, spare parts availability.