In the dynamic world of snack food packaging, vertical form-fill-seal (VFFS) machines have emerged as game-changing solutions for popcorn producers worldwide. With the global popcorn market projected to grow from $8.8 billion in 2024 to $14.89 billion by 2029, representing a compound annual growth rate of 11.10%, efficient packaging technology isn't just advantageous—it's essential for market competitiveness -1.

This comprehensive guide explores how VFFS machines specifically transform popcorn packaging operations, delivering unprecedented efficiency, product protection, and branding opportunities.

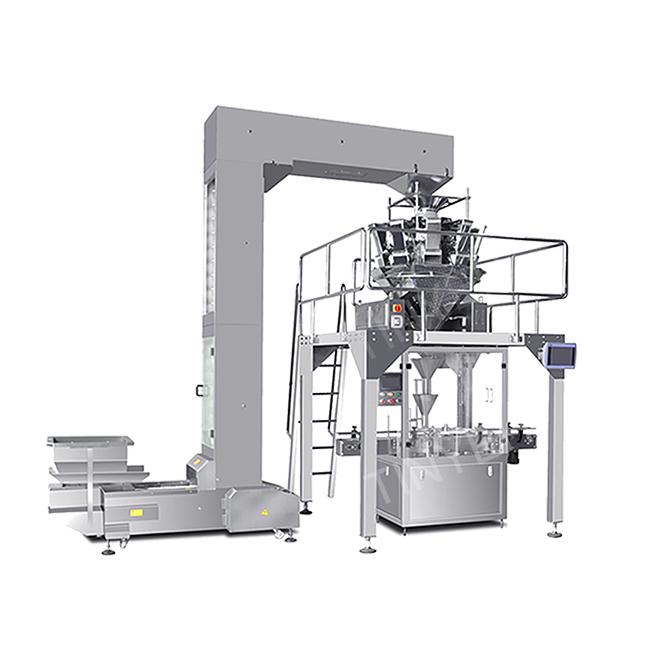

Understanding VFFS Machines for Popcorn Packaging

Vertical form-fill-seal machines are automated systems that form packaging from roll stock, fill it with product, and seal it in one continuous operation. For popcorn packaging, these machines offer distinct advantages over alternative methods like pre-made bags or manual twisting of plastic bags -1.

The packaging process typically follows these steps:

-

Film Feeding: Roll stock material unwinds and travels through the machine's guidance system

-

Tube Formation: The film forms into a cylindrical shape around a filling tube

-

Vertical Sealing: The film's edges seal vertically to create a continuous tube

-

Horizontal Sealing & Bottom Closure: The top and bottom seals create individual bags

-

Product Filling: Precise portions of popcorn discharge into the formed bags

-

Top Sealing & Separation: The filled bags receive top seals and separate from the film continuum

Technical Advantages of VFFS Machines for Popcorn

Enhanced Efficiency and Speed

VFFS machines dramatically increase production output while reducing labor requirements. These systems can package hundreds of popcorn bags per minute, far surpassing manual or semi-automated alternatives. This efficiency becomes particularly valuable during seasonal demand peaks or large production runs -1.

Superior Product Protection

Popcorn's freshness and crispness depend on effective protection from moisture, oxygen, and physical damage. VFFS machines create hermetically sealed packages using multi-layer laminated barrier films that shield popcorn from:

-

Moisture and vapor that would make popcorn soggy

-

Oxygen that causes staleness

-

UV light that degrades quality

-

Physical impacts during shipping and handling

The tight seals maintain product integrity from production to consumption, ensuring customers enjoy the same fresh, high-quality popcorn every time -1.

Packaging Versatility

VFFS technology accommodates an impressive range of packaging formats specifically beneficial for popcorn:

-

Pillow bags for standard retail packaging

-

Gusseted bags that allow standing on shelves

-

Various seal configurations for different opening experiences

-

Multiple size options from single-serving to family-size packages

This flexibility enables popcorn producers to diversify their product lines without investing in separate packaging equipment -1.

Critical Considerations for Popcorn VFFS Applications

Material Selection

Successful popcorn packaging with VFFS machines depends heavily on selecting appropriate packaging materials. Key considerations include:

Film Coefficient of Friction (COF)

-

Inadequate COF causes film slippage or misalignment during processing

-

Ideal COF values typically range around 0.25 for smooth machine operation

-

Uneven COF across film surfaces leads to tracking problems and machine jams

Industry case studies have demonstrated that films with excessively low COF (approximately 0.13) cause significant operational issues in VFFS systems -3.

Barrier Properties

-

Moisture barrier protection to maintain crispness

-

Gas barrier properties to prevent oxidation

-

Seal layer integrity for strong, consistent seals

Machine Configuration for Popcorn

Optimizing VFFS machines for popcorn requires specific technical considerations:

Product Handling Systems

-

Gentle handling mechanisms to prevent kernel breakage

-

Vibration-free mounting to maintain accurate weighing

-

Static control systems to manage popcorn's tendency to generate static electricity

Weighing and Filling Technology

-

Multi-head weighers for precise portion control

-

Customized buckets and chutes accommodating popcorn's irregular shapes

-

Dust management systems to handle fine particles from popcorn handling

Overcoming Common VFFS Challenges in Popcorn Packaging

Film Tracking and Slippage

As identified in packaging studies, film slippage remains a common challenge in VFFS operations. Solutions include:

-

Regular COF testing of incoming film materials

-

Maintaining clean traction rollers and film path components

-

Proper tension control throughout the film path

-

Environmental controls to maintain stable temperature (ideally 22±2°C) and humidity (55-60%) -2

Product Bridging and Inconsistent Filling

Popcorn's irregular shape and tendency to interlock can cause:

-

Bridging in hoppers and feed systems

-

Inconsistent fill weights

-

Production slowdowns or stoppages

Mitigation strategies include:

-

Specialized agitation systems to prevent bridging

-

Optimized drop heights and chute designs

-

Regular verification of scale accuracy

Maintenance Considerations

Proper maintenance ensures consistent VFFS machine performance:

-

Daily cleaning of product contact surfaces

-

Regular inspection of sealing jaws for debris buildup

-

Periodic verification of temperature control systems

-

Lubrication schedules following manufacturer recommendations

The Future of VFFS Technology in Popcorn Packaging

Innovation in VFFS technology continues to enhance popcorn packaging capabilities:

Intelligent Monitoring Systems

-

AI-powered vision systems detecting seal defects or filling issues

-

Real-time weight monitoring with automatic adjustment

-

Predictive maintenance alerts based on operational data

Sustainability Advancements

-

Compatibility with recyclable films meeting evolving environmental standards

-

Material optimization reducing film consumption without compromising integrity

-

Energy-efficient operation lowering environmental impact

Enhanced Flexibility

-

Quick-changeover systems accommodating multiple package sizes and formats

-

Digital parameter storage for different product configurations

-

Integrated printing systems enabling variable data and limited editions

Implementing VFFS Solutions: Strategic Approach

For popcorn producers considering VFFS technology, a structured implementation approach proves most effective:

-

Production Volume Assessment

-

Evaluate current and projected production needs

-

Determine appropriate machine capacity with growth margin

-

-

Packaging Portfolio Strategy

-

Identify required package styles, sizes, and materials

-

Ensure machine flexibility matches product roadmap

-

-

Integration Planning

-

Assess facility requirements including space, power, and environmental controls

-

Plan production line integration with existing upstream and downstream equipment

-

-

Supplier Selection

-

Partner with experienced VFFS manufacturers familiar with food applications

-

Verify service and support capabilities for ongoing maintenance

-

-

Operator Training

-

Implement comprehensive training programs for operations and maintenance staff

-

Establish documentation systems for procedures and troubleshooting

-