As the global snack industry continues to grow, so does the need for efficient, reliable, and cost-effective snack packaging solutions. From small businesses entering the food production market to large-scale snack manufacturers expanding their operations, one critical investment is the snack packaging machine. But how much does a snack packaging machine cost, and what factors influence its price? This article provides a detailed breakdown of costs, machine types, features, and market considerations to help you make an informed purchasing decision.

Understanding the Snack Packaging Machine

A snack packaging machine is a type of automated equipment designed to package various snack products—such as chips, nuts, popcorn, granola bars, or dried fruits—into retail-ready pouches or containers. These machines are essential for maintaining product freshness, enhancing shelf appeal, and complying with food packaging regulations.

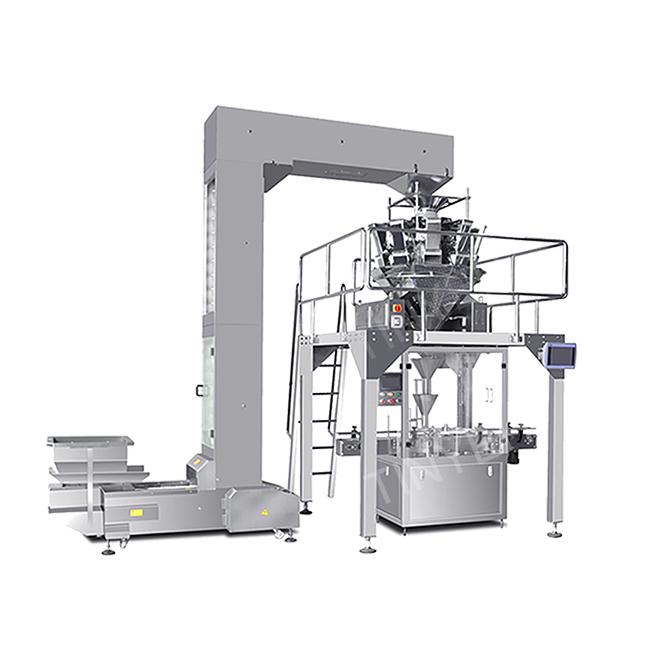

Modern snack packaging systems come in different formats and sizes, each tailored to specific packaging needs. From vertical form fill seal machines (VFFS) to multi-head weigher packaging systems, these machines can be configured to handle a wide range of snack food applications.

Tinyeh Snack Packaging Machine

How Much Does a Snack Packaging Machine Cost?

The cost of a snack packaging machine varies widely based on several factors:

| Machine Type | Typical Price Range (USD) |

| Entry-level Manual Packaging Units | $3,000 – $8,000 |

| Semi-automatic Machines | $8,000 – $20,000 |

| Fully Automatic Systems | $25,000 – $150,000+ |

| Customized High-Speed Lines | $150,000 – $500,000+ |

Let's examine the different categories:

Entry-Level Manual Units: Manual or tabletop machines are ideal for small-scale operations or startups producing limited volumes. These machines usually require human intervention for bag feeding or sealing. While affordable, they may not offer the high-speed automation that large operations need.

Semi-Automatic Snack Packaging Machines: These machines offer a balance between manual operation and automation. Often used in medium-sized businesses, they automate parts of the process—like sealing or filling—while still needing some manual handling. Examples include semi-automatic granule packaging machines or powder packing systems for seasoning snacks.

Fully Automatic Packaging Systems: These machines are designed for high-volume production. They typically include automated weighing, filling, sealing, cutting, and coding systems. Brands like Effytec, Ishida, or Matrix Packaging Machinery offer modular solutions that can integrate into a larger food processing line.

Customized High-Speed Production Lines: For multinational brands or major food factories, custom snack packaging solutions with robotic pick-and-place systems, inline quality inspection, and multi-lane pouch packaging are used. These machines are often engineered specifically for the client's product, packaging material, and required throughput.

Factors Influencing Snack Packaging Machine Cost

1. Automation Level

As mentioned above, machines with higher automation levels cost more due to their ability to reduce labor costs and increase productivity.

2. Packaging Type and Material

Snack products can be packaged in a variety of formats:

● Pillow bags

● Gusseted bags

● Stand-up pouches (Doypack)

● Sachets

● Zipper bags

● Vacuum bags

More complex packaging formats require advanced machine configurations, which drive up the cost.

3. Output Capacity (Speed)

Machines with higher speeds (e.g., 60–120 packs per minute) require more robust components, precise servo motors, and high-speed weighing and filling technology. This adds to the cost significantly.

4. Product Characteristics

Snacks vary greatly in size, shape, and texture. Machines for free-flowing products (like nuts) are generally simpler than those handling sticky or irregular-shaped snacks (like dried mango slices or energy balls), which may require custom feeding systems.

5. Brand and Country of Origin

Machines manufactured in the USA, Germany, or Japan tend to be more expensive due to engineering standards and component quality. However, Chinese snack packaging machine manufacturers offer competitive pricing while continuously improving on automation and durability.

Additional Costs to Consider

Beyond the machine's sticker price, there are additional costs to factor in:

● Shipping and import duties

● Installation and commissioning fees

● Operator training

● Spare parts and maintenance

● After-sales support and warranty

A vendor's reputation for technical support and machine reliability can justify a higher upfront cost.

Key Applications of Snack Packaging Machines

Snack packaging machines are used across a broad spectrum of food products:

● Chips and crisps

● Nuts and trail mix

● Granola and energy bars

● Candy and chocolate bites

● Popcorn

● Baked snacks

● Dehydrated fruits and vegetables

In each case, the machine must be adapted for hygiene, speed, and accuracy, and comply with food safety certifications such as CE, ISO, or FDA.

Features to Look For in a Snack Packaging Machine

Choosing the right configuration not only impacts price but also long-term operational efficiency. When evaluating a machine, consider the following features:

● PLC Control Panel with Touchscreen – for easy operation and real-time monitoring

● Automatic Weighing System – such as a multi-head weigher for precision

● Nitrogen Flushing System – extends the shelf life of oxygen-sensitive snacks

● Date Printer / Expiry Code Printer

● Bag Former Customization – for different pouch shapes

● Servo Motor Drives – increase packing accuracy and reduce mechanical failures

● Tool-Free Changeovers – ideal for businesses that produce different snacks

Snack Packaging Machine Trends in 2025 and Beyond

Emerging trends are influencing machine design and innovation:

● Sustainable Packaging Compatibility – Machines are being adapted to handle recyclable and biodegradable films

● Smart Factory Integration – Machines now support IoT and remote diagnostics

● Flexible Packaging Systems – Supporting multiple product types and sizes

● Compact Footprints – For SMEs with space constraints

● Energy-Efficient Designs – Reducing power consumption

These trends may increase upfront costs but offer ROI through long-term sustainability, energy savings, and adaptability.

Conclusion: What Should You Expect to Pay?

Investing in the right snack packaging solution means analyzing not just the price tag, but also how the machine fits into your broader production line, your market goals, and your plans for future growth.

In summary, a snack packaging machine could cost anywhere from $3,000 to over $500,000, depending on your production scale, packaging requirements, and automation preferences. For startups, semi-automatic or entry-level systems offer a good balance of affordability and performance. For established manufacturers, fully automated, customizable systems can deliver higher speed, efficiency, and compliance. Compare features, automation levels, and manufacturers. Get the best packaging solution for your snack business.