In modern manufacturing, especially in food, pharmaceuticals, cosmetics, chemicals, and agricultural sectors, automated packing machines are essential. But not all packing machines are the same. The choice among granule packaging machines, powder packaging machines, and liquid packing machines depends heavily on the physical characteristics of the product to be packaged. In this article, we'll dive into the differences between granule, powder, and liquid packing machines, analyze their mechanisms, advantages, and typical applications.

Fundamental Differences: Granule, Powder, Liquid

Granule: Particles that are small and discrete but have a definite size (e.g., coffee granules, sugar crystals, rice, seeds). They are solid and typically free-flowing but coarse compared to fine powders.

Powder: Very fine particulate matter (e.g., flour, spices, infant formula, pharmaceutical powders) which may tend to compact, generate dust, or behave differently under flow. Powders often require more careful handling.

Liquid: Fluids ranging from water-thin (e.g., water, juices) to viscous (e.g., sauces, oils, lotions) that flow and conform to container shapes.

Because of these physical differences, the mechanisms, accuracy, sealing, and cleaning requirements of packing machines differ. A machine optimized for liquids may fail with powders (e.g., spilling, inaccurate fill), and vice versa.

Granule Packing Machines

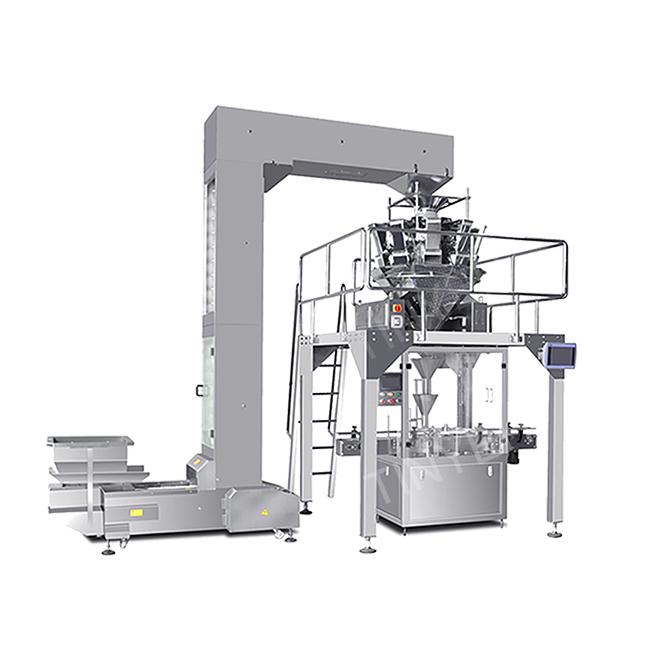

Automatic Granule Vertical Weighing Packing Machine

Filling methods

Granule packing machines typically use volumetric or gravimetric (weighing) methods:

Volumetric cup fillers: Use fixed cups or scoops that measure a certain volume of granules, then drop them into the bag or container. If density is fairly uniform, this gives acceptable accuracy.

Multi-head weighers (or multi-head weigh fillers): Multiple weighing heads combine to select a combination of heads whose total weight is closest to the target weight. This improves speed and accuracy.

Loss-in-weight feeders: Especially for continuous operations, the machine monitors the weight loss in a hopper and feeds material accordingly.

Sealing / bag forming

Granule packaging is often done with a vertical form-fill-seal (VFFS) machine, which forms the bag, fills it, and seals it in one continuous motion.

Suitability

Because granules are more forgiving than fine powders, granule machines can run at higher speeds, have fewer issues with clogging, and tolerate small fluctuations in flow.

Powder Packaging Machines

Full Automatic Powder Packing Machine

Filling methods

Packing fine powders demands more delicate mechanisms:

Auger fillers: Use a rotating screw (auger) to deliver a precise amount of powder from the hopper to the bag/container. This is among the most common methods for free-flowing powders.

Volumetric fillers: For powders of consistent density, volumetric paddles or cups can be used.

Vacuum-assisted or vacuum belt feeding: For non-free-flowing powders, vacuum systems help draw powder into the dosing chamber.

Net weight or gravimetric filling: For high accuracy, weight-based dosing ensures exact quantity.

Anti-dust and sealing

Powder machines often include dust extraction or enclosed filling zones, and may require anti-static or de-dusting devices to reduce airborne powder, improve sealing, and reduce contamination.

Cleaning and maintenance

Because powders tend to cling, cake, or clog, powder packaging machines typically require more frequent cleaning, calibration, and inspection. Many come with CIP (clean-in-place) features or detachable parts for easy cleaning.

Liquid Packing Machines

Automatic Liquid Vertical Packing Machine

Filling methods

Liquid filling machines use approaches suited to fluid behavior:

Gravity filling (for low-viscosity liquids): The liquid flows by gravity into the container.

Pump filling (for moderate to viscous liquids): A pump (e.g., peristaltic, piston, gear pump) meters the fluid volume precisely.

Piston filling: A piston draws and dispenses a precise volume of liquid.

Overflow or level-fill: Ensures each container is filled to a consistent height.

Timed flow or volumetric filling: Opens a valve for a set time to deliver a measured dose.

Sealing / bag forming / capping

With liquids, spills, drips, and inaccuracies can be costly. Liquid packing machines often integrate anti-drip nozzles, valves with shut-offs, and synchronized conveyors. They also may integrate capping, sealing, or induction sealing for bottles or sachets.

Cleaning and hygiene

Liquid machines usually demand robust sanitary design (316 stainless steel, sanitary fittings), quick cleanability, and minimal dead zones to prevent contamination. Some have CIP or SIP (sterilize-in-place) capabilities.

Granule vs. Powder vs. Liquid Packing Machines

| Feature | Granule Packaging Machine | Powder Packaging Machine | Liquid Packing Machine |

| Product type | Coarse solid particles (e.g., sugar, rice, pet food) |

Fine powders (e.g., flour, spices, supplements) |

Fluids / viscous liquids (e.g., sauces, juices, oils) |

| Filling mechanism | Volumetric cups, multi-head weighers, loss-in-weight |

Auger fillers, volumetric paddles, vacuum-assisted |

Gravity, pump, piston, timed flow, overflow |

| Speed / throughput | Generally high | Moderate to high (may be slower with fine powders) |

High for low-viscosity; slower for viscous fluids |

| Accuracy / tolerance | Acceptable variance due to the discrete particle nature |

Higher precision is needed to avoid underfill or overfill |

Moderate to high accuracy, valve control |

| Dust / spillage risk | Low | High requires dust control, enclosed filling |

Risk of leaks or drips sealing mechanisms |

| Cleaning complexity | Moderate | High | High (sanitary, CIP) |

| Typical challenges | Bridging, segregation at extremes |

Caking, static charge, flow variability |

Viscosity changes, foaming, dripping |

| Ideal industries | Food grains, snacks, seeds, pet feed | Food powders, pharmaceutical powders, cosmetic powders |

Beverages, condiments, chemicals, and personal care liquids |

In short, granule machines are relatively robust and forgiving, powder machines require precision and dust control, and liquid machines demand hygienic design and handling of fluid behavior.

Applications of the 3 Packing Machine Types Across Industries

Food and Beverage

Granule machines: Package items like sugar, salt, cereals, rice, snack nuts, coffee beans, and pet food granules.

Powder machines: Used for flour, spice mixes, milk powder, beverage mix powders, protein powders, powdered soup, and sand seasoning.

Liquid machines: Bottle or sachet filling of juices, sauces, oils, syrups, dressings.

Pharmaceuticals & Nutraceuticals

Granule machines: Some pharmaceutical granules or beadlets, capsule fill granules.

Powder machines: Tablets, medicinal powders, supplement powder blends, baby formula.

Liquid machines: Syrups, suspensions, tonics, liquid medicines.

Cosmetics & Personal Care

Powder machines: Face powders, talc, dry cosmetic powders, mask powders.

Liquid machines: Lotions, shampoos, liquid soaps, creams (semi-liquids).

Granule packaging is less common here, but might apply to pearl beads, bath salts, or exfoliating beads.

Chemical & Industrial

Granule machines: Packaging granular chemicals, detergents (when in granule or pellet form), fertilizer, and plastic granules.

Powder machines: Chemical powders, pigments, cementitious additives, detergent powders.

Liquid machines: Industrial chemicals, acids, cleaning agents, lubricants, adhesives (in liquid or gel form).

How to Choose the Right Packing Machine for Your Line?

Match Product Properties

First, characterize your product:

● Is it granular, powder, or liquid?

● Is the powder free-flowing or prone to caking?

● What viscosity does your liquid have?

● Does it foam or contain particulates?

It determines whether you need a granule, powder, or liquid packing machine.

Required Accuracy and Tolerance

For high-value or highly regulated products (e.g., pharmaceuticals), tighter tolerances demand gravimetric or weighing-based machines. A volumetric granule machine might suffice for bulk grains with looser tolerances.

Speed and Throughput

Consider your production target. Granule machines can often run faster; powder and liquid machines may need more time per unit. Make sure your chosen machine can keep up.

Cleanability, Maintenance, and Downtime

Especially for powders and liquids, the ease of cleaning is critical. Machines with clean-in-place (CIP), easy disassembly, and minimal dead zones reduce downtime.

Integration, Control, and Automation

Modern packaging lines integrate conveyors, labelers, metal detectors, and control systems (PLC, HMI). Choosing machines that support line integration ensures smoother operation.

Total Cost & ROI

While granule machines may cost less, the cost of errors, waste, downtime, and cleaning must be included. Return-on-investment (ROI) considerations often favor higher-end machines for critical products.

Tinyeh offers custom packing solutions — tell us your product, capacity, and constraints, and we design and deliver an integrated system with the right combination of granule, powder, and liquid machines.

Best Practices of Different Packing Machines

Powder Aggregation and Flow

Fine powders may clump, bridge in the hopper, or display inconsistent bulk density. Best practices:

Use agitation or vibrators in the hopper.

Use anti-static or vibration devices.

Select the auger pitch or design carefully.

Enclose walls to reduce dust and segregation.

Segregation in Granules

When granules of varying particle sizes are mixed, segregation may occur (finer particles settle). Use mixing strategies, maintain consistent granule size control, and optimize feed rate to reduce segregation.

Viscosity and Foam in Liquids

Highly viscous products or foaming liquids complicate filling. Use degassing, temperature control (heaters), pumps with gentle flow, and anti-drip nozzles.

Cleaning and Cross-Contamination

Especially in pharma, cross-contamination is disastrous. Use easy dismantling, CIP systems, validated cleaning protocols, and proper materials (e.g., stainless steel).

Calibration and Maintenance

Frequent calibration (especially for powder machines) ensures accuracy. Schedule preventive maintenance, replace wear parts, and maintain proper documentation.

FAQ: Granule vs. Powder vs. Liquid Packing Machines

1. What is the main difference between granule, powder, and liquid packing machines?

The key difference lies in the product type each machine handles.

● Granule packing machines are designed for solid particles such as sugar, coffee, or rice.

● Powder packaging machines are used for fine powders like flour, milk powder, or spices.

● Liquid packing machines fill and seal fluids, including water, sauces, oils, and creams.

Each machine uses different filling mechanisms suited to product flow and density.

2. How does a granule packing machine work?

A granule packing machine typically measures product by volume or weight using devices like volumetric cups or multi-head weighers. It then drops the granules into pouches or bags formed on a vertical form-fill-seal (VFFS) system, seals them, and cuts the bags automatically.

3. What types of powders can a powder packaging machine handle?

Powder packaging machines can handle free-flowing powders (like coffee powder or protein mix) and non-free-flowing powders (like flour or baby formula). Depending on powder behavior, they use auger fillers, vacuum feeders, or net weight systems to ensure accuracy and dust-free operation.

4. Can the same packing machine be used for both granules and powders?

Generally, no. While some semi-universal systems exist, the filling principles for powders and granules differ significantly. Powders often require auger or vacuum filling systems, while granules rely on volumetric or weighing systems.

Using one machine for both can reduce accuracy and cause product contamination.

5. What is a liquid packing machine used for?

A liquid packing machine is used for filling and sealing liquid or semi-liquid products like juice, detergent, honey, or shampoo. It can use gravity, pump, or piston filling depending on the viscosity.

Modern systems can also integrate anti-drip nozzles and CIP (clean-in-place) features to maintain hygiene.

6. Which industries use granule, powder, and liquid packaging machines?

These machines serve a wide range of industries:

● Food & Beverage (snacks, spices, sauces, drinks)

● Pharmaceutical & Nutraceutical (medicine powders, syrups)

● Cosmetics & Personal Care (lotions, creams, face powders)

● Chemicals & Agriculture (fertilizer, detergents, oils).

7. How do I choose the right packing machine for my product?

You should consider:

● Product form (granule, powder, liquid)

● Flowability or viscosity

● Required fill accuracy

● Packaging speed

● Hygiene requirements

● Integration with your production line

Consulting with a packaging solution provider like Tinyeh ensures you get the right configuration for your needs.

8. What is an auger filler, and why is it important in powder packaging?

An auger filler uses a rotating screw to measure and dispense a precise amount of powder into packaging. It is ideal for controlling fill weight, reducing dust, and maintaining accuracy — essential for pharmaceutical, food, and chemical powders.

9. How are hygiene and cleaning handled in packing machines?

Modern packing machines, especially for food and liquids, use stainless steel construction, sealed chambers, and CIP (Clean-in-Place) systems. These features prevent contamination, simplify maintenance, and meet GMP or food-safety standards.

10. Why choose Tinyeh for packaging machines?

Tinyeh offers all three types of machines — granule, powder, and liquid packing machines — and provides customized packing solutions for diverse industries.

With expertise in automation, integration, and after-sales support, Tinyeh helps businesses improve productivity, consistency, and packaging quality.

Conclusion

Choosing between a granule packing machine, a powder packaging machine, and a liquid filling (packing) machine begins with understanding your product's physical nature. Granule machines suit coarse, flowable solids; powder machines require precision, dust control, and advanced dosing systems; liquid machines demand hygienic design, precise pumps or valves, and anti-drip mechanisms.

Selecting the correct machine type or combining them into a comprehensive line, you can maximize efficiency, ensure accurate filling, reduce waste, and simplify operations. Tinyeh stands ready to supply all three types of machines, tailor the integration across industries, and deliver packing solutions that span food, pharmaceuticals, cosmetics, chemicals, agriculture, and more.

Browse our wide range of packing machines for different products.