What is a Vertical Packaging Machine?

A Vertical Form-Fill-Seal (VFFS) machine is an automated system designed to create packages from a roll of flat packaging film, fill them with a specific product, and hermetically seal them—all in a continuous vertical operation. For potato chips, these machines are engineered to handle the product's low density and fragility while ensuring high-speed production.

How Does a Vertical Packager Work for Potato Chips?

The process is a marvel of engineering efficiency:

-

Film Feeding: A roll of packaging material (typically a multi-layer laminate for barrier properties) is mounted on the machine. The film is fed downward into a forming collar.

-

Tube Formation: The forming collar shapes the flat film into a continuous vertical tube around a filling tube.

-

Vertical Sealing: The longitudinal back seal of the tube is created by a vertical sealer.

-

Cross Sealing & Filling: The top and bottom of the package are created simultaneously by a pair of horizontal sealing jaws. As the jaws close to seal the bottom of one bag, they also seal the top of the previous bag. Pre-weighed potato chips are dropped through the filling tube into the newly formed bag below.

-

Cutting & Discharge: The finished, sealed bag is cut from the tube and discharged onto a conveyor belt for collection, casing, or palletizing.

Key Features of a High-Quality Potato Chips Packaging Machine

Not all VFFS machines are created equal. For optimal chip packaging, look for these essential features:

-

Gentle Product Handling: Specialized augers or vibratory feeders ensure fragile chips are not crushed during the filling process.

-

High-Speed Operation: Modern machines can achieve speeds of 80-120+ bags per minute, maximizing your production output.

-

Advanced Gas Flushing (Nitrogen Flushing): This is critical for potato chips. The machine injects nitrogen gas into the bag before the final seal, displacing oxygen to prevent oxidation (rancidity) and protect the chips from being crushed during transit—creating the iconic "pillow pack."

-

User-Friendly PLC (Programmable Logic Controller): A touchscreen HMI allows for easy recipe changes, parameter adjustments, and troubleshooting, minimizing downtime.

-

Sanitary & Easy-to-Clean Design: Machines with stainless steel contact parts and minimal crevices ensure compliance with food safety standards (like HACCP and GMP).

-

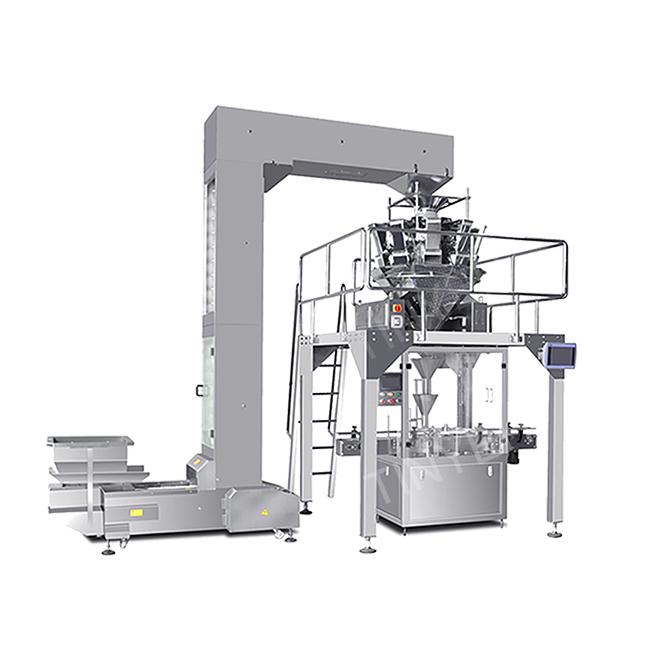

Precision Weighing System: Integrated multi-head weighers or auger feeders provide exact weight measurements, reducing product giveaway and ensuring compliance with regulatory standards.

Major Benefits of Using a Vertical Packaging Machine

Investing in a specialized VFFS machine for chips offers significant advantages:

-

Enhanced Product Freshness & Shelf Life: The hermetic seal and nitrogen flushing preserve the chip's crispness, flavor, and aroma for much longer.

-

Increased Production Efficiency: Automation leads to higher output with less manual labor, lowering your cost per bag.

-

Reduced Material Waste: Using roll stock film is more cost-effective than pre-made bags and allows for quick size changes with minimal waste.

-

Excellent Packaging Integrity: Strong, consistent seals prevent leaks and protect the product from moisture and contaminants.

-

Brand Versatility: Easily switch between different bag sizes and designs, allowing for flexible packaging for various chip flavors, brands, or promotional campaigns.

Choosing the Right Vertical Packaging Machine for Your Needs

When selecting a machine, consider these factors:

-

Production Volume: Determine your required bags-per-minute rate.

-

Bag Size Range: What are the minimum and maximum bag dimensions you need?

-

Packaging Materials: Ensure the machine is compatible with your specific film type (e.g., metallized polypropylene, laminated films).

-

Level of Automation: Consider integration with checkweighers, metal detectors, and case packers for a fully automated line.

-

Supplier Reputation & Support: Choose a manufacturer known for reliability, quality, and excellent after-sales service and spare parts availability.